Ive recently purchased a bf50d outboard and have been troubleshooting and trying to get it to run correctly.

From the beginning I was able to get it to run barely and stay at idle by first pouring fuel into the cylinders and it fired up and idled somewhat. I could rev it and it would hesitate a little and make some rpm then usually fall back and die. It would be very hit or miss after that, mostly not even starting. I tested for spark at each plug and had strong spark. checked all fuses which were showing continuity. Decided to clean out the fuel vst and purge the lines from the fuel tank all the way up to the high pressure fuel rail. I found that the fuel was in bad condition. Cleaned everything and put it back together and left the line off the high pressure rail. Pumped the fuel bulb in order to fill vst and then turned key to "on" position and it sprayed a strong burst of fuel out. Decided to crank the engine and see what it would do and it made a strong continuous stream. But after that it while repeating the same test it got weaker with each test. Decided to hook it up, repump fuel bulb, and tried to start and would only start then cough and die. Took the fuel rail connection off and now there was zero output on the fuel line while cranking. Checked all connections under cowling for any corrosion. Motor was previously ran in a freshwater environment.

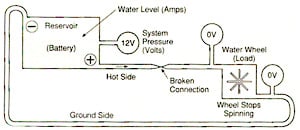

From there we hardwired the fuel pump to the positive terminal at starter and it will fire and run almost perfectly without any hesitation and rev up and seemingly have no issues. Will fire right up every time. I wasnt able to make out if the fuel pump was an aftermarket or an oem becuase of slight corrosion on pump housing. I did however use an ammeter to see what the pump was drawing while hard wired and running and it was at a steady 4.77amps. I am willing to spend some money on this project but the parts can add up very quickly and am willing to do the trouble shooting if anyone is willing to shoot me something to try. Any and all questions welcome. Thanks in advance.

From the beginning I was able to get it to run barely and stay at idle by first pouring fuel into the cylinders and it fired up and idled somewhat. I could rev it and it would hesitate a little and make some rpm then usually fall back and die. It would be very hit or miss after that, mostly not even starting. I tested for spark at each plug and had strong spark. checked all fuses which were showing continuity. Decided to clean out the fuel vst and purge the lines from the fuel tank all the way up to the high pressure fuel rail. I found that the fuel was in bad condition. Cleaned everything and put it back together and left the line off the high pressure rail. Pumped the fuel bulb in order to fill vst and then turned key to "on" position and it sprayed a strong burst of fuel out. Decided to crank the engine and see what it would do and it made a strong continuous stream. But after that it while repeating the same test it got weaker with each test. Decided to hook it up, repump fuel bulb, and tried to start and would only start then cough and die. Took the fuel rail connection off and now there was zero output on the fuel line while cranking. Checked all connections under cowling for any corrosion. Motor was previously ran in a freshwater environment.

From there we hardwired the fuel pump to the positive terminal at starter and it will fire and run almost perfectly without any hesitation and rev up and seemingly have no issues. Will fire right up every time. I wasnt able to make out if the fuel pump was an aftermarket or an oem becuase of slight corrosion on pump housing. I did however use an ammeter to see what the pump was drawing while hard wired and running and it was at a steady 4.77amps. I am willing to spend some money on this project but the parts can add up very quickly and am willing to do the trouble shooting if anyone is willing to shoot me something to try. Any and all questions welcome. Thanks in advance.