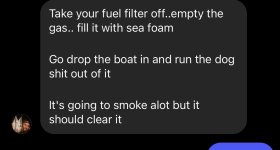

So i did my carbs a few months ago and the boat ran great for 3 outings. It was giving a sputter at trolling speed every minute or so and I turned the fuel screw to 2 turns out and it went away (suspect it was a lean sputter?). Today after trolling around the creeks for a few hours it started the sputter again so i tried to get on plane and it was cutting out badly could not do it. I let the motor cool and switched fuel tanks and didn’t help. Got progressively worse to the point i barely made it back to the dock: The fuel is only 2 weeks old ethanol free with treatment in it. I did notice the middle carb seems to have a slight amount of fuel leaking from the float bowl seam/drain area (weird bc all new gaskets) but it didn’t seem to be coming from the vent (stuck float). Upon bringing it home i lowered the motor to flush and it started and ran great with a higher idle. Revenge slightly did not bog out but of course there was no load. Could be bad fuel (but unlikely) or moisture in filter but l looks like i’m going to have to pull apart the carbs which is crazy after less than 10 hours. Any ideas and would i have to get all new gaskets again? The look nice and new/green still. Btw i let the motor cool down on the water just too rule out an issue with heat (air leak/ignition coil) and it did not help.

Home

Outboard Motor Parts

Chrysler outboard parts Evinrude outboard parts Force outboard parts Honda outboard parts Johnson outboard parts Mariner outboard parts Mercury outboard parts Suzuki outboard parts Tohatsu outboard parts Yamaha outboard partsInboard & Sterndrive Engine Parts

Chrysler Marine inboard parts Crusader Marine parts MerCruiser sterndrive parts OMC sterndrive parts Pleasurecraft Marine parts Volvo Penta marine parts + MoreAll Engine Brands

All Manuals HomeOutboard Repair Manuals

Chrysler outboard manuals Evinrude outboard manuals Force outboard manuals Honda outboard manuals Johnson outboard manuals Mariner outboard manualsMercury outboard manuals Nissan outboard manuals Suzuki outboard manuals Tohatsu outboard manuals Yamaha outboard manuals

Inboard & Sterndrive Engine Manuals

MerCruiser sterndrive manuals OMC sterndrive manuals Volvo Penta marine engine manualsPlease Note

MarineEngine.com does not offer troubleshooting assistance or repair advice by email or by telephone.

You are invited to join our public Boat Repair Forum to seek assistance from other members.

You may also visit the Boat Motor Manuals section of our site to obtain a service manual.