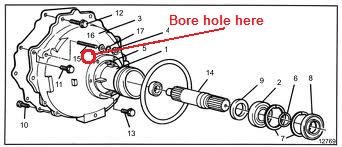

I was told you do not want the baring to go bad on shaft from motor. I have a 1995 Ford powered 302 Volvo penta. My reserarch says its a single baring unit. Should be able to pull it from rear. I wish now I would of left it alone. I have huge slide hammer and a brass pipe cut open to squeeze and protect splines. I have to best biggest vise grips money can buy. I can only tighten it so tight with big channels helping. I get several big hits before it slips off. I've moved the shaft about 1 inch out. The baring is now between the to large C clips groves. It will not move anymore. I even took a 3 pound hammer and hit it forward. Wont move forward either. Havent tryed my 13 pounder yet. What the heck is going on? If I could just hold on tighter without slipping off. I even took my Drimmel tool and made a C clip grove on edge of shaft slid a brass pipe over it put a C Cip on and still hold tight enough. How can it move 1" and no more? I don't want to pull motor although it mabe enevitable. May not be able to pull it anyway with a stuck shaft. Been working on this for about 1 month. May never get the boat back in water. What started to be maintance is ending up to be the worse decision ever. I am a decent mechanic rebuilding cars, other boats, sea doos. work at Ford as mechanic for years. It shows to be single baring. I dont believe I could of moved it an inch if it was a double baring. The boat had sat for 3 years. RUST maybe. Help

Home

Outboard Motor Parts

Chrysler outboard parts Evinrude outboard parts Force outboard parts Honda outboard parts Johnson outboard parts Mariner outboard parts Mercury outboard parts Suzuki outboard parts Tohatsu outboard parts Yamaha outboard partsInboard & Sterndrive Engine Parts

Chrysler Marine inboard parts Crusader Marine parts MerCruiser sterndrive parts OMC sterndrive parts Pleasurecraft Marine parts Volvo Penta marine parts + MoreAll Engine Brands

All Manuals HomeOutboard Repair Manuals

Chrysler outboard manuals Evinrude outboard manuals Force outboard manuals Honda outboard manuals Johnson outboard manuals Mariner outboard manualsMercury outboard manuals Nissan outboard manuals Suzuki outboard manuals Tohatsu outboard manuals Yamaha outboard manuals

Inboard & Sterndrive Engine Manuals

MerCruiser sterndrive manuals OMC sterndrive manuals Volvo Penta marine engine manualsPlease Note

MarineEngine.com does not offer troubleshooting assistance or repair advice by email or by telephone.

You are invited to join our public Boat Repair Forum to seek assistance from other members.

You may also visit the Boat Motor Manuals section of our site to obtain a service manual.