Hi, I tested the compression on my merc 50 hp today, cant say I like the results... The engine was cold and I dont have a startermotor so I cranked the flywheel with a wrench a few turns on each cylinder. Motor was cold and all the plugs were out. This is the results (psi)

1 58

2 51

3 0

4 51

From what I understand theese compression sucks so I double checked the gauge on my yamaha 6 hp. On that I have a rope starter so I turn much faster then with the wrench on the 50 hp. On the Yamaha I got over 100 psi with both plugs out-

So Im wondering what might cause this? Did I did something when measuring on my mercury? Could it be the cylinder head gasket? If not what could it be? Any advice forward would be appreciated.

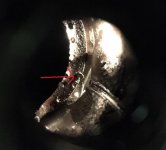

Has anyone changed the head gasket on a motor like this? The bottom bolts are hard to reach, do I remove the engine mount (marked with red arrows) in order to access them or do I have lift the entire powerhead out? Also what is the bolt next to cyl 3 indicated by the green arrow?

1 58

2 51

3 0

4 51

From what I understand theese compression sucks so I double checked the gauge on my yamaha 6 hp. On that I have a rope starter so I turn much faster then with the wrench on the 50 hp. On the Yamaha I got over 100 psi with both plugs out-

So Im wondering what might cause this? Did I did something when measuring on my mercury? Could it be the cylinder head gasket? If not what could it be? Any advice forward would be appreciated.

Has anyone changed the head gasket on a motor like this? The bottom bolts are hard to reach, do I remove the engine mount (marked with red arrows) in order to access them or do I have lift the entire powerhead out? Also what is the bolt next to cyl 3 indicated by the green arrow?