Maintenance like U-joint greasing, etc. was only learned earlier this year when talking with a co-worker who has some limited knowledge, being an owner himself. I could kick my own *** for not learning a bit more about these when I initially bought it, and hope I've done no damage in the meanwhile.

Anyhoo ... back to the problem at hand ...

I've started tearing back into things before reading the last couple of replies from you fellas ...

I tore off the lower unit yesterday hoping only to get a look at the where the oil was seen coming from, and to determine how it got there.

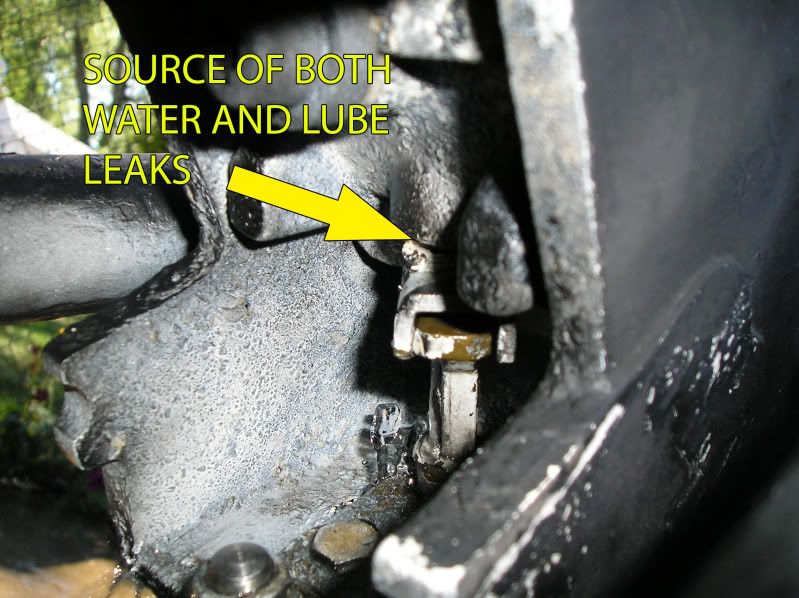

Here's my first look:

Now, as described earlier ... after last running it on muffs, I naturally had water slowly dripping from here first, for a short while after shut down, followed by oil. This was with the unit trimmed up so naturally, some water would pool here in this position and any oil would float to the top of it, coming after the water COULD drain, drained to this point.

After a day, I trimmed down and the balance of the water and a tiny bit of oil drained ...

My logic at this point, and correct me if it isn't sound is that this oil can't be truly coming down the shift shaft necessarily (from the rubber seal bt doctur described) because if it were, it would continue to leak here and pool up in the water pump area (exhaust passageways) ... or so I think.

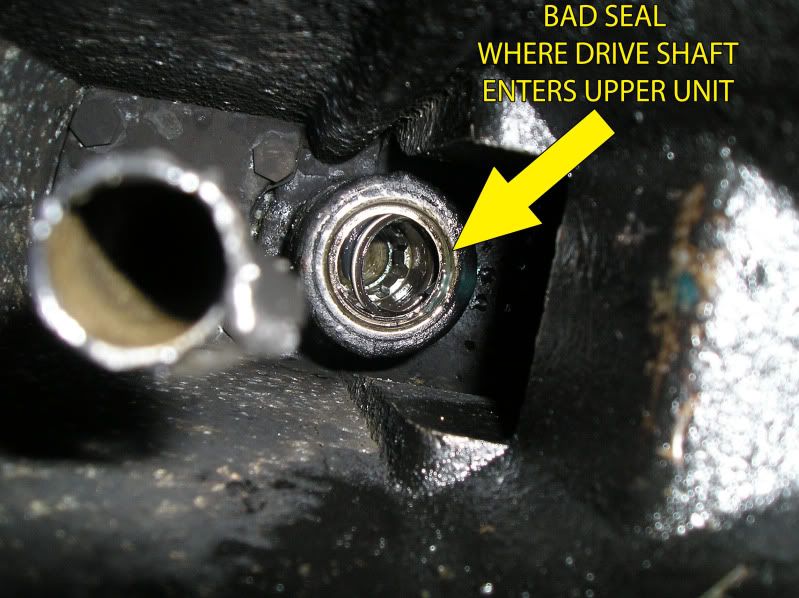

Further examination however did reveal this:

So if I'm looking at the schematics correctly, this seal retains oil in the upper gear housing and being blown could perhaps allow oil into the exhaust area via the drive shaft, and possibly only when the unit is running, under pressure, and not allow water back upward, thus explaining the lack of water in the oil. Even sitting idle, my logic tells me that this seal is above the water line (or damn near), so other than incidental splash from the exhaust area it would not see sustained water exposure to allow water to eventually penetrate and pollute the oil.

This is my logic anyway, and correct me please if it's not sound. The old girl also has an o-ring on the drive shaft near the top that was torn (even though it was replaced when the water pump work was done) ... and the seal appeared good at the time of the water pump work ... although it was obviously not ... perhaps damaged from heat during the water pump failure?

So that's where I'm at ... still haven't pulled the entire unit ... just the lower, based on time constraints yesterday afternoon.

I can't discern if the seal is #29 or #30 on the drawing that bt doctur provided in the link above, but I suspect replacing both is obviously prudent.

Does the entire upper unit have to be torn down to access this seal, and is this seal pressed in?

Thanks again for all of the correspondence guys, I'm learning a good deal here as I go along.