I have a 150 Johnon Fasstrike with the following challenge:

At WOT & 5400 - 5500 RPM it runs ok for 15 seconds then surges to 3500 - 4000 RPM - I reduce the gas lever and it runs ok at 4500 RPM. Maximum stabil RPM = 5000 RPM.

The oil (VRO system) is not connected and I premix the fuel.

Boat - Fjordling 18' about 600 KG exclusive engine

Propeller Raker 14 3/4 x 22

When I get someone to pump the primer pump gently at 5500 RPM it runs ok.

Some of the components in my fuel system was not 3/8' but this is now rebuilt.

Vacum at WOT in the fuel line is 3 to maybe 4 HG.

I have a 1 m clear fuel line connected - formed as a vertical "ring" circle before the vaccummeter - there is small a air bubble on top of the ring - but no "stream" of air in the line.

The fuel pump "clicks" every 10 second at 1000 RPM.

Is there anyone that can suggest anything ?

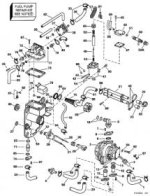

Should I maybe consider to change to a premix pump P/N 5007422 ?

At WOT & 5400 - 5500 RPM it runs ok for 15 seconds then surges to 3500 - 4000 RPM - I reduce the gas lever and it runs ok at 4500 RPM. Maximum stabil RPM = 5000 RPM.

The oil (VRO system) is not connected and I premix the fuel.

Boat - Fjordling 18' about 600 KG exclusive engine

Propeller Raker 14 3/4 x 22

When I get someone to pump the primer pump gently at 5500 RPM it runs ok.

Some of the components in my fuel system was not 3/8' but this is now rebuilt.

Vacum at WOT in the fuel line is 3 to maybe 4 HG.

I have a 1 m clear fuel line connected - formed as a vertical "ring" circle before the vaccummeter - there is small a air bubble on top of the ring - but no "stream" of air in the line.

The fuel pump "clicks" every 10 second at 1000 RPM.

Is there anyone that can suggest anything ?

Should I maybe consider to change to a premix pump P/N 5007422 ?

Last edited: