tundrarules

Regular Contributor

Great discussion by all....still waiting for the advance timing graph for my 318s

...1 year old distributors and no clue as to what springs I should install.:rolleyes::rolleyes::rolleyes:

...1 year old distributors and no clue as to what springs I should install.:rolleyes::rolleyes::rolleyes:

MarineEngine.com does not offer troubleshooting assistance or repair advice by email or by telephone.

You are invited to join our public Boat Repair Forum to seek assistance from other members.

You may also visit the Boat Motor Manuals section of our site to obtain a service manual.

Jeff, again, I am not a Chrysler Marine expert under any stretch of the imagination, but having years of marine experience, I can't help but question the 2,500-2,800 rpm being suggested for a "full-in" rpm.Basically, if the advance is all the way in by 2,500-2,800 rpms, you're all set.

1.... didn't someone post a BASE advance spec of 5* BTDC?1.... I did some research and found some specs 10-12 base and 32-34 all in or total advance but there still was not a specific all in rpm.

2..... MSD does have the electronic advance dizzy that works with a knock sensor but not sure if one is available for the early marine 318. It will retard the timing when detonation occurs and fully adjustable.........

3..... Another thread said if the timing is off it will make the starter labor real hard so that would be another consideration in base timing.

4.... Somthing in the back of my head is telling me the mopar curve takes two stages or two springs rather agressive up to 1800 rpm like 15 degrees then around 3000 be all in. Maybe looks something like this is just an example you have to correctly determine TDC?

5...... 10 degrees base at 800rpm

15 degrees advance at 1800rpm

7 degrees at 3000rpm

that adds to 32 dbtdc at 3000 rpm all in

6..... slack in the second spring allows the two stages of advance

7..... Someone must have the top secret clearance willing to leak the advance curve for a early marine 318. Maybe wiki leaks could find out or someone in the oval office.

Jeff, I'm not sure which of Kim's suggestion you make reference to. With the unknowns, that may be risky, especially re; the lower 2,500 rpm.That's too much for a 318; I wouldn't exceed 26 degrees total all in at 2,500- 2,800 rpms................. Going to 28 or even 30 degrees might improve gas mileage, but gas is cheaper than rebuilds!found some specs 10-12 base and 32-34 all in or total advance

that adds to 32 dbtdc at 3000 rpm all in

Question: if these are new Marine distributors, why a spring change or curve change?Great discussion by all....still waiting for the advance timing graph for my 318s...1 year old distributors and no clue as to what springs I should install. :rolleyes::rolleyes::rolleyes:

I would agree on both points!Same here the numbers I gave were for a example I couldnt find the thread I read a while back but yea 5 degrees base and 20-22 degree advance giving 25-27 all in at whatever rpm between 2800-3200 I would imagine safe from detonation but we still need solid numbers to work by from chrysler.

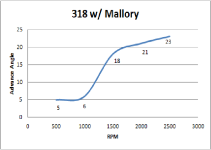

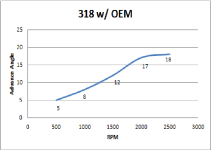

So the mallory was All in at 2500? or could it do more?

JJ, that would be good! I'm hopeful that you will see a performance increase.When I install the new Mallory on my port engine this weekend, I'll run them both up to 3000 and update the curves.

Could it do more in what regard? More degress of advance, or more RPM until Full-In?[B said:greasemonkey][/B] So the mallory was All in at 2500? or could it do more?

I would take it apart clean all the weights and springs(everything) with a dremel wire wheel lube it with a thin oil like marvel put a rubber hose on a punch and slide the other end on the distributor shaft stop and start a bunch of times put it back in and see what happens...just remember the difference in the 2 springs and where they went.

Im starting to wonder if the 318s can see 40knots on a 31 silverton

Jfreeman, is it possible that the tachometer is not reading accurately, and the engine was actually doing greater than 2,900 rpm?

Be careful with the flyweight returns springs in that you don't stretch them, and be sure to put both flyweights and springs back where they came from.

While the pivot pins may be in the same location on either, the spring tang will not be tweaked the same for each spring value.

I would take it apart clean all the weights and springs(everything) with a dremel wire wheel lube it with a thin oil like marvel put a rubber hose on a punch and slide the other end on the distributor shaft stop and start a bunch of times put it back in and see what happens...just remember the difference in the 2 springs and where they went.

Dry weight is 8100 lbs I believe.

Quick question.

If I'm looking at the front of my engine and it rotates counter clockwise. While looking at the timing indicator on the harmonic balancer. To the left is after top center and the right is before top center. There are no markings other then lines on it.