A little background -

I bought a 40+ year old boat. It didn't have the original drive train but had been updated to a 260A motor w/ 250 outdrive. I bought a complete spare 250 outdrive for parts, but it was for a 4 cylinder, not an 8 like mine. I tore up the anti-ventilation plates on my 250 and didn't want to change out the gearbox on the replacement 250 (4cyl), so I bought a complete 280 for my V8. I then decided to just repair my 250, so the original 250 is still on the boat and I have a working 250 4 cyl and a working 280 8 cyl in addition to the 250 8 cyl on the boat.

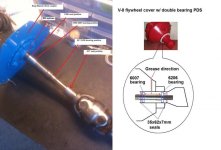

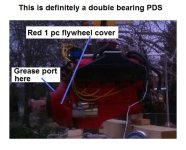

So I'm playing with the 280 in preparation to use it if/when. Here's the 280 8 cyl and 250 4 cyl which I have been told are pretty much interchangeable except for the lower section.

We know the 250 takes a short hub propeller and the 280 can take either. Is the only difference in the prop cone assembly the hole in the end of the cone?

I know the cone with the hole can be used with the 250 because that's what I have on the boat now with the 250 and it works just fine using the tangs without the center bolt.

So I need a 'long hub' line cutter and what else to mount the short hub prop on the 280?

And if I want to use a long hub prop on the 280, what additional stuff do I need in addition to the long hub line cutter? Maybe just an 850888 plastic washer?

The 250 isn't tapped for a cone bolt. I see cone bolts on sale for over $20 but they can be had at Home Depot for less than $2. All I really need to know is how long?

I'd asked if there might be a difference in the helmet bolt going from the 250 to the 280, but find that the 250 bolt fits just fine in the 280.

It's nice that they even have the torque spec etched on the top of the helmet bolt.

We talked about the oil fill hole on the 280 being substantially higher than the required level, so I'll use the level as shown on the dipstick.

So my last question for now is about the hose connecter on top of the outdrive. I need one and can't decide what part number it is...the 250 and 280 appear to be identical but some are only 2 hole and are some called 'thermostat housing'?

Oh, and when you use heat to free up a stuck bolt, do you apply heat directly to the head of the bolt or to the housing it's seated in? And if the bolt itself - how hot - do you need to get it red?

I bought a 40+ year old boat. It didn't have the original drive train but had been updated to a 260A motor w/ 250 outdrive. I bought a complete spare 250 outdrive for parts, but it was for a 4 cylinder, not an 8 like mine. I tore up the anti-ventilation plates on my 250 and didn't want to change out the gearbox on the replacement 250 (4cyl), so I bought a complete 280 for my V8. I then decided to just repair my 250, so the original 250 is still on the boat and I have a working 250 4 cyl and a working 280 8 cyl in addition to the 250 8 cyl on the boat.

So I'm playing with the 280 in preparation to use it if/when. Here's the 280 8 cyl and 250 4 cyl which I have been told are pretty much interchangeable except for the lower section.

We know the 250 takes a short hub propeller and the 280 can take either. Is the only difference in the prop cone assembly the hole in the end of the cone?

I know the cone with the hole can be used with the 250 because that's what I have on the boat now with the 250 and it works just fine using the tangs without the center bolt.

So I need a 'long hub' line cutter and what else to mount the short hub prop on the 280?

And if I want to use a long hub prop on the 280, what additional stuff do I need in addition to the long hub line cutter? Maybe just an 850888 plastic washer?

The 250 isn't tapped for a cone bolt. I see cone bolts on sale for over $20 but they can be had at Home Depot for less than $2. All I really need to know is how long?

I'd asked if there might be a difference in the helmet bolt going from the 250 to the 280, but find that the 250 bolt fits just fine in the 280.

It's nice that they even have the torque spec etched on the top of the helmet bolt.

We talked about the oil fill hole on the 280 being substantially higher than the required level, so I'll use the level as shown on the dipstick.

So my last question for now is about the hose connecter on top of the outdrive. I need one and can't decide what part number it is...the 250 and 280 appear to be identical but some are only 2 hole and are some called 'thermostat housing'?

Oh, and when you use heat to free up a stuck bolt, do you apply heat directly to the head of the bolt or to the housing it's seated in? And if the bolt itself - how hot - do you need to get it red?