RicardoMarine

Gold Medal Contributor

Rather than further Hi-Jack Jfreeman's thread, I thought that I'd begin a new thread.

First... I'm not a Chrysler Marine expert in any stretch of the imagination.

Secondly..... I'm not posting this to degrade or bash the Chrysler systems.

Thirdly...... this is a proposal and question thread only, simply based on some of my observations of the Chrysler raw water cooling systems whereby the dual pocket belt driven pump is used.

Questions first:

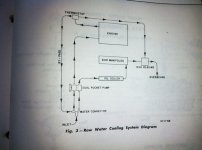

The Dual Pocket sea water pumps and engine and exhaust plumbing systems appear to be overly complex to me, and would appear to offer issues that other systems do not routinely offer.

Again, I'm not an expert on these systems, but have recently been looking at them on the forum here.

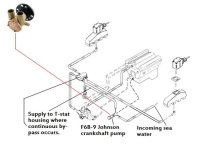

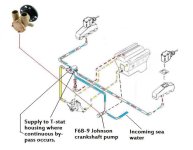

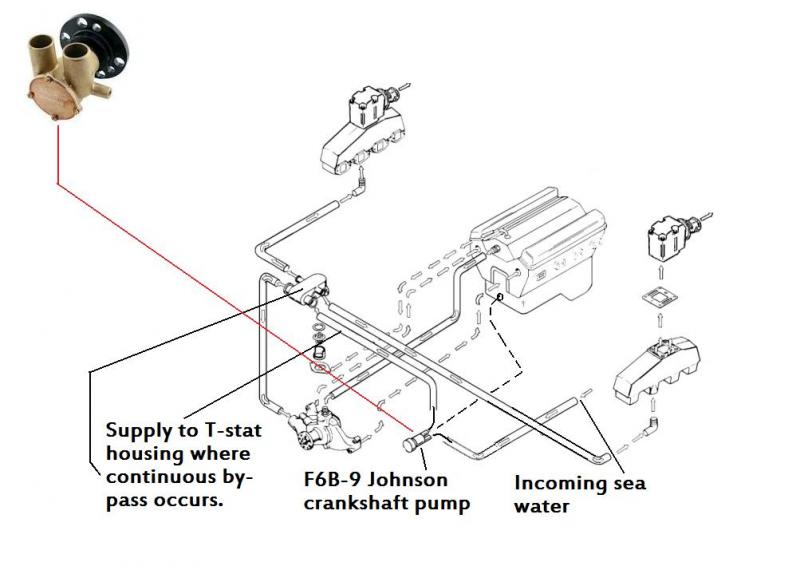

This image below may be similar to the typical dual pocket pump sea water cooling system layout.

(this is not my image... I found it while doing a search)

To me, this system appears to be more complicated than need be.

My experience is that the belt driven sea water pumps intrinsically delay or defer maintenance due to the pump requiring removal in order to change an impeller. Not just Chrysler's belt driven pumps.... most all belt driven pumps... Merc, Volvo Penta and others included!

Most any of us who work in this field routinely address over-heating issues simply because an owner does not perform pump/impeller maintenance frequently enough.

I find that those owners with crankshaft style pumps, tend to stay more on top of it... IMO.

(again.... not my image)

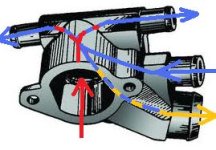

Many raw water cooled Marine engines are fitted with the crankshaft style pump.

Take a look at how simple the plumbing is.

The T-stat housing allows for the By-Pass to occur within the body of the housing.

As with any engine, the engine circulating pump "charges" the engine block with a supply of cool sea water.

T-stat opens, allows cooling water to escape as needed, and this "spent" sea water is then directed back into the exhaust system supply.

Meanwhile, the balance of the pump's sea water is continuously flowing onto and out the exhaust system.

Granted, this change may be quite involved, but it would be a one-time deal ONLY.

It may also require a different style exhaust manifold/riser configuration.... you guys would know more about that!

It would require some adaptation to the crankshaft pump base plate as to fit the Chrysler front engine pulley/balancer.

It would also require enough space in front of the engine for the pump location.

But again..... it would be a one-time deal ONLY.

What are your thoughts?

.

First... I'm not a Chrysler Marine expert in any stretch of the imagination.

Secondly..... I'm not posting this to degrade or bash the Chrysler systems.

Thirdly...... this is a proposal and question thread only, simply based on some of my observations of the Chrysler raw water cooling systems whereby the dual pocket belt driven pump is used.

Questions first:

- Are you guys OK with the belt driven dual pocket pumps, and do these systems seem to be trouble-free?

- Do these seem to be overly complex?

- Do these pose any issues routinely?

- Do these systems appear to defer routine maintenance related to impeller and/or pump inspection?

- Would a single crankshaft pump, and a more simple exhaust cooling water system, benefit you?

- Do you think that the crankshaft style pump system could be incorporated?

- Or would it be best to leave things alone?

The Dual Pocket sea water pumps and engine and exhaust plumbing systems appear to be overly complex to me, and would appear to offer issues that other systems do not routinely offer.

Again, I'm not an expert on these systems, but have recently been looking at them on the forum here.

This image below may be similar to the typical dual pocket pump sea water cooling system layout.

(this is not my image... I found it while doing a search)

To me, this system appears to be more complicated than need be.

My experience is that the belt driven sea water pumps intrinsically delay or defer maintenance due to the pump requiring removal in order to change an impeller. Not just Chrysler's belt driven pumps.... most all belt driven pumps... Merc, Volvo Penta and others included!

Most any of us who work in this field routinely address over-heating issues simply because an owner does not perform pump/impeller maintenance frequently enough.

I find that those owners with crankshaft style pumps, tend to stay more on top of it... IMO.

(again.... not my image)

Many raw water cooled Marine engines are fitted with the crankshaft style pump.

Take a look at how simple the plumbing is.

The T-stat housing allows for the By-Pass to occur within the body of the housing.

As with any engine, the engine circulating pump "charges" the engine block with a supply of cool sea water.

T-stat opens, allows cooling water to escape as needed, and this "spent" sea water is then directed back into the exhaust system supply.

Meanwhile, the balance of the pump's sea water is continuously flowing onto and out the exhaust system.

Granted, this change may be quite involved, but it would be a one-time deal ONLY.

It may also require a different style exhaust manifold/riser configuration.... you guys would know more about that!

It would require some adaptation to the crankshaft pump base plate as to fit the Chrysler front engine pulley/balancer.

It would also require enough space in front of the engine for the pump location.

But again..... it would be a one-time deal ONLY.

What are your thoughts?

.

Attachments

Last edited: