Thanks to all!!

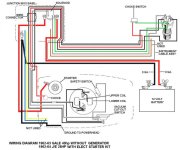

I was able to get spark. I disconnected the wires on the center post of the cut out switch and pulled the flywheel and cleaned the points. Wiring wise this is what I found: a black wire (along with the green coil and condenser wire) on each of the point terminals, one of the wires went directly to the center term of the cut out switch, the other went to the kill switch first then to the center term of the cut out switch, on the corner post of the C/O switch was a white wire that goes to a micro switch next to the ignition plate that is activated by a cam. Seems to me both cylinders would be cut out with this setup???

The plug wire with the dot was on the top spark plug is this correct? It goes to the coil on the side with the C/O switch

Thanks Again!!