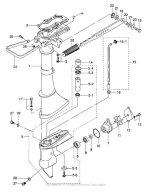

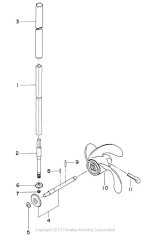

Good day all, I’ve got foamy oily goo running from the weep holes between the gear case and shaft housing so I’m assuming The seal on the drive shaft is shot. I would also assume the time would be right to change the seal on the prop shaft as well. However it appears f rom the schematics that the upper seal would be exposed to water, hence the notable leak, but the prop shaft seal is behind the water pump case though there doesn’t appear to be a water seal of any kind on the prop shaft between the impeller and the oil seal so I guess there must be water in there as well. Are these seals able to be changed without special tools if care is used and are ther likely to be bearing issues I should prepare myself for. Have I seen that Nissan/Tohatsu parts are availabl e here somewhere? Hope all your projects go well and thank you all for being here. Best, Peter

Home

Outboard Motor Parts

Chrysler outboard parts Evinrude outboard parts Force outboard parts Honda outboard parts Johnson outboard parts Mariner outboard parts Mercury outboard parts Suzuki outboard parts Tohatsu outboard parts Yamaha outboard partsInboard & Sterndrive Engine Parts

Chrysler Marine inboard parts Crusader Marine parts MerCruiser sterndrive parts OMC sterndrive parts Pleasurecraft Marine parts Volvo Penta marine parts + MoreAll Engine Brands

All Manuals HomeOutboard Repair Manuals

Chrysler outboard manuals Evinrude outboard manuals Force outboard manuals Honda outboard manuals Johnson outboard manuals Mariner outboard manualsMercury outboard manuals Nissan outboard manuals Suzuki outboard manuals Tohatsu outboard manuals Yamaha outboard manuals

Inboard & Sterndrive Engine Manuals

MerCruiser sterndrive manuals OMC sterndrive manuals Volvo Penta marine engine manualsPlease Note

MarineEngine.com does not offer troubleshooting assistance or repair advice by email or by telephone.

You are invited to join our public Boat Repair Forum to seek assistance from other members.

You may also visit the Boat Motor Manuals section of our site to obtain a service manual.