1995 Mercruiser 5.7L Magnum EFI (TBI) Tournament Ski

Ser. # 0F562552

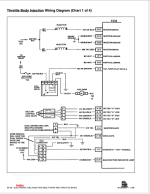

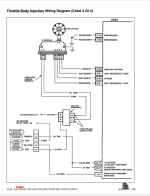

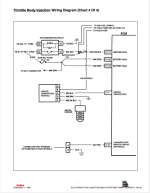

This boat ran great all last season and was put to bed in October with zero problems. De-winterized it today and no start. Fuel pump is pumping but injectors are not spraying. This is the TBI system, not the MPI, with two injectors mounted on a throttle body that's sitting on the intake manifold where the carb would usually be. I'll be dragging out the shop manual. Any trouble shooting tips appreciated.

Many thanks for your help, PW

Ser. # 0F562552

This boat ran great all last season and was put to bed in October with zero problems. De-winterized it today and no start. Fuel pump is pumping but injectors are not spraying. This is the TBI system, not the MPI, with two injectors mounted on a throttle body that's sitting on the intake manifold where the carb would usually be. I'll be dragging out the shop manual. Any trouble shooting tips appreciated.

Many thanks for your help, PW