I have completed the relocation of the outboard mount. The first test was successful in that the motor began spitting water right away, though I haven't put it through the true first test of taking the boat out, lifting the motor out, keep it out for a few hours of sailing, then tilt back down to come in. That will be the real test.

However I did run it for a bit at the dock. Unfortunately it did overheat (overheat alarm sounded and I shut it down) while idling. I would estimate it took about 2 to 2.5 minutes (from cold start) of idling before it overheated.

I took off the recoils starter from the flywheel (I let it dangle by the neutral/in-gear disengage, as suggested - thanks for that tip!) and used my new handheld tachometer. The idle seems to be at ~ 1,400 RPM, if the cheapo tachometer is reading correctly, so I am not sure how much more I could realistically increase the idle speed to help with the overheating problem.

I did let it cool, and started it up again, to run the rest of the fuel out of the carb and lines. I did my usual trick of holding up the fast idle lever a little bit, to increase the RPMs and boost the amount of water pumped up into the head, and as usual that trick did work, and the motor ran for several more minutes without overheating.

I did notice a new thing, which is now when I turn the motor off (and/or when it ran itself out of gas), now there is a bit of water that drains out from the pisser after the motor is still and silent - this is a good improvement, because previously when the motor stopped, the water from the telltale immediately ceased flowing.

Anyway, I guess I'll have to look up the idle RPM specs unless anyone here happens to remember off the top of their head. I will probably experiment a bit with the idle settings to see what is the lowest RPM it needs to keep from overheating, even if I cannot permanently adjust the idle speed that high (worried about it being too high to safely go from neutral into gear).

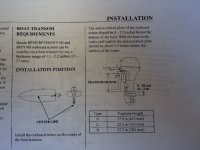

Here are a couple of pictures; forgive my dangling recoil starter. It's tough to see but with nobody aboard the top fin of the cavitation plate is about an inch above the water line and with me in the cockpit, that is about flush with the water.

Thanks again for everyone's comments!