Well, I'd first recommend that the components be varified as to the correct interchangeability and correct shimming.

If they missed the issue of the 250 -vs- the later components, they may have also missed something else.

NOTE: Again, the PZNR tag on your transmission clearly says that it is a 250.

All 250's use the small (3.345" OD) driven gear angular contact bearings..... period!

NOTE: Any Intermediate that does NOT have the fill port, is the next generation for the mid-size (3.545" OD) angular contact driven gear bearing.

These two components should not be mated!

NOTE: All lower units can be interchanged!

Yesterday I measured the bore of a 270/275/280/285 Intermediate housing (the mid-size bearing OD) just to varify......, and to compared this to the smaller 250 driven gear bearing OD.

- 270/275/280/285 Intermediate housing bearing/shim landing measures........ 3.545"

- The 250 small driven gear bearing OD measures ....................................... 3.345"

That is a discrepancy of .200"... or just shy of 1/4".

However, there appears to be plenty of landing for both the 270/280 shims and the outer lip of the 250 bearing....

but this is not done typically!

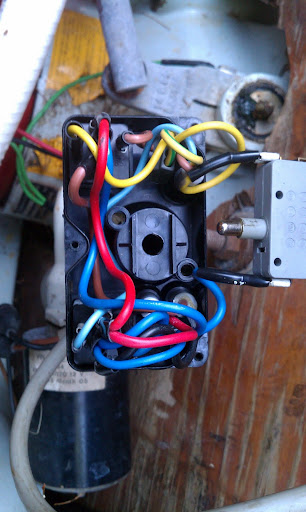

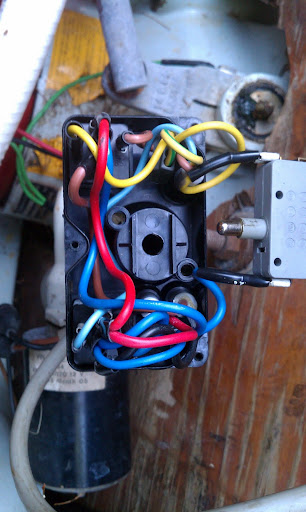

The black arrows show where the bearing seats;

(the other arrows were for another demonstration)

.