backbaychal

Member

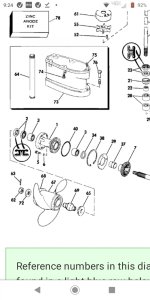

according to service manual it shows the only thrust washer on these lower units fits between bearing housing and retainer plate. Thrust washer is tapered on one side so to appears to sit in center of retainer plate. has anyone ever worked on 1984 Evinrude 35 hp and is placing it in retainer plate tapered side to gears correct? service manual does not address this . can anyone shed light I attached a photo.

Attachments

Last edited: