Haha all good tim! lemme explain - the test is done disconnected first to isolate the stator and see if it can "pump" the volts required.. Then you connect the pack bare minimum (no kill wire/coils/etc) - if the voltage drops significantly the pack is faulty cos its not supposed to drain the juice, so a good pack connected will show near or similar volts as compared to the stator disconnected -

ie a bad pack will show a significant to complete loss of power when connected (as in my case).

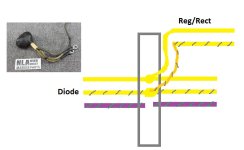

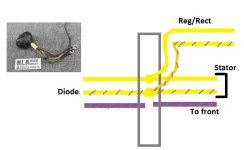

More theory, the stator provides 2 paths of juice, high voltage for the pack (150-400 volts). The (usually yellow) wires are much lower, maybe 18 or 35 volts, ALL they do is charge the battery - NOTHING else. JUST charging the battery, hence the much lower voltage - the rectifier/regulator takes the 18 or 30 volts and converts it to DC and down to say 13.5 or 14.3 (safe charging voltage).

Thats why you test the pack wire from the stator (brown in my case) disconnected first, then connected- so in my video you can see I get 186 volts disconnected - which is plenty.. (spec is 150 to 400). Then when I connect it to the pack I get 0.5v or something, a good pack would still read high, maybe a few volts less but maybe 5-10 volts.

The end result is a bad pack will literally drain all the juice out of the stator (internal problem) - this is the way to test a pack.. now if the voltage was low connected AND disconnected, obviously the stator is bad-

Aren't you supposed to do the stator test while it's connected as well as disconnected up to the pack? Why?.....To make certain it doesn't drop while it's loading the capacitor in the pack, eh? The reading shouldn't change if your having a "good day"!

So reviewing back to the very first post it looks like the reading drops to nothing....I'm so stupid, I missed it, sorry! Dah? Coulda saved you some trouble.