RicardoMarine

Gold Medal Contributor

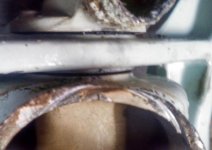

Simple method to remove the carrier from the prop shaft if you do not own the Volvo Penta fixtures:

Loosen the bearing retaining ring nuts a bit.

Apply some heat to the aluminum carrier housing to expand it.

Gently drop the AFT end of the prop shaft against a soft wooden block.

The carrier's enertia will cause it to drop some until the nuts restrict movement.

Now finish loosening and removing the nuts.

Gently drop assembly again, and the carrier should slide free from the bearing.

The adjusting shims will be either within the carrier or may be stuck to the bearing, or both.

The seal replacement will be pretty much self explanatory.

Reassembly will be pretty much in the oposite order.

No need to remove the bearing from the propeller shaft unless:

The slinger pump impeller drive pins have sheared off.

The main thrust load angular contact bearing will be replaced.

Forgive my rather crude image!

Loosen the bearing retaining ring nuts a bit.

Apply some heat to the aluminum carrier housing to expand it.

Gently drop the AFT end of the prop shaft against a soft wooden block.

The carrier's enertia will cause it to drop some until the nuts restrict movement.

Now finish loosening and removing the nuts.

Gently drop assembly again, and the carrier should slide free from the bearing.

The adjusting shims will be either within the carrier or may be stuck to the bearing, or both.

The seal replacement will be pretty much self explanatory.

Reassembly will be pretty much in the oposite order.

No need to remove the bearing from the propeller shaft unless:

The slinger pump impeller drive pins have sheared off.

The main thrust load angular contact bearing will be replaced.

Forgive my rather crude image!