I've searched this on the forum and I don't see if this has been addressed. I removed my elbows and manifold from my 1979 225D to inspect them recently. As I had a cracked exhaust hose and some visible rust marks near the elbow and manifold joint.

The information here on the hose length was very helpfull by the way.

Yes..... the 95mm exhaust couplers should be approx 1-1/2" to 2" longer than the OEM couplers were.

The longer length ensures that the band clamps can be pulled further up the Elbow as to prevent compressing the couplers into the scalloped areas!

So I am in process of ordering new gaskets and from what I can tell the correct replacement blocks two of the ports? And is only open with a pinhole. This is the same gasket that was currently installed. Is there an explanation for this?

Yes, as you can see the FORE and AFT seawater transfer ports become blocked off by the gasket (minus the small weep holes).

The remaining open seawater transfer ports carry the manifold seawater to the Elbow and out via the mixing chamber.

The weep holes are there to ensure that the Elbow drains completely during winterizing!

Lastly how many lbs should these bolts be torqued when reinstalling?

Follow your OEM work shop or service manual instructions.

These threads are also a great place for the Automotive Never-Seez product (not the Marine version).

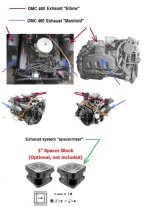

Side note: There is no Riser (aka Spacer) available for the AQ225D style exhaust system.

The down-angle of the 95mm Elbow outlet would prevent the use of a Riser/Spacer.

I've searched this on the forum and I don't see if this has been addressed. I removed my elbows and manifold from my 1979 225D to inspect them recently. As I had a cracked exhaust hose and some visible rust marks near the elbow and manifold joint. The information here on the hose length was very helpfull by the way.

I've searched this on the forum and I don't see if this has been addressed. I removed my elbows and manifold from my 1979 225D to inspect them recently. As I had a cracked exhaust hose and some visible rust marks near the elbow and manifold joint. The information here on the hose length was very helpfull by the way.