Webbtronjr

Member

Hi!

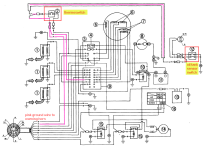

I have a 1987 yamaha 90hp outboard jet motor that is going into limp mode after about 1-2 minutes of operation. When I bought the boat 4 years ago, the oil pump was bypassed already. When it goes into safe mode the motor is running fine it is just at reduced RPM. No missing or sputtering. I have a service manual, and as far as I can see the only two reasons for it to do this would be the Temp sensor switch and the oil sensor switch. I ran the test on the heat sensor and it appears to switch off and on within the temp limits. I recently changed the water pump impeller and it shows a strong steam of water exiting the motor. I ran tests on the oil sensor too but I am curious, can I disconnect all those wires since it is bypassed? at a loss... any help would be appreciated. Thanks in advance

I have a 1987 yamaha 90hp outboard jet motor that is going into limp mode after about 1-2 minutes of operation. When I bought the boat 4 years ago, the oil pump was bypassed already. When it goes into safe mode the motor is running fine it is just at reduced RPM. No missing or sputtering. I have a service manual, and as far as I can see the only two reasons for it to do this would be the Temp sensor switch and the oil sensor switch. I ran the test on the heat sensor and it appears to switch off and on within the temp limits. I recently changed the water pump impeller and it shows a strong steam of water exiting the motor. I ran tests on the oil sensor too but I am curious, can I disconnect all those wires since it is bypassed? at a loss... any help would be appreciated. Thanks in advance