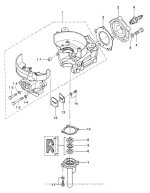

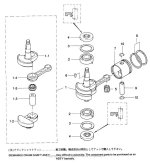

I have a NS5B 5 HP 2-stroke that had a bad lower bearing so I am replacing it along with the top bearing and top and bottom seals. Does anyone know the torque specs for the crankcase bolts and in which order for when I put it back together?

I believe I should use a thin bead of Loctite 518 on one side of the crankcase but would like confirmation.

I took the old bearing and put in toaster oven at 250 deg for 10 minutes and it slipped right over the crankshaft for a test, could that much heat hurt the new bearing?

Last questions, the top seal the lip faces down which I know but what about the bottom seal? It looks like on the diagrams that faces down too, is that right? Should I use a little Permatex Aviation Form-A-Gasket around the top and bottom seals and then seat it?

Thank you, I appreciate it!

I believe I should use a thin bead of Loctite 518 on one side of the crankcase but would like confirmation.

I took the old bearing and put in toaster oven at 250 deg for 10 minutes and it slipped right over the crankshaft for a test, could that much heat hurt the new bearing?

Last questions, the top seal the lip faces down which I know but what about the bottom seal? It looks like on the diagrams that faces down too, is that right? Should I use a little Permatex Aviation Form-A-Gasket around the top and bottom seals and then seat it?

Thank you, I appreciate it!