I recently bought a 1972 Magnum 27' Sedan that has the Chrysler/Volvo outdrives and 2 360 engines, I know they were originally 318 or 340 motors but that is not my concen. The boat is from CT and spent its life in saltwater, the drives were nasty, hose clamps and wire cables locking them down because the revers lock mechanisms were rusted solid, covered with Barnacles, the steering was frozen on both drives. I had to cut the suspension arms to get them off as the bolts for the pins were siezed and stripped, tried my best with PB-40 Aerokroil and heat, got 1 out of the 4 bolts out and finally said the heck with it, I want to replace them with freshwater units anyway.

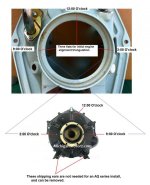

I have a few questions, I was able to get the Helmets off of the drive and steering forks, I also got the bolts out that hold the retaining ring to the bell housing. How do I get the retaining rings out?

I also want to upgrade to the 290 / SP CD Trim style transom assys to get power trim. I understand I will have to enlarge the cutout in the transom, and may have to move the engines forward a little?

Finally the 270 outdrives I have shift nice and turn smoothly so I'm thinking the internals are good. If I were to buy a V6 or 4Cyl SP drive woud the gearsets from the lower housing in my 270 work in the SP case? just a thought as I have found more 4 and 6 cyl SPs than 8 cyl ones locally, and it was just a thought. Either way I plan on tearing down whatever drives I get to make sure everything is n working order before I install them in the boat. Thanks Murf

Warning if you are squeamish dont look at these pics!

I have a few questions, I was able to get the Helmets off of the drive and steering forks, I also got the bolts out that hold the retaining ring to the bell housing. How do I get the retaining rings out?

I also want to upgrade to the 290 / SP CD Trim style transom assys to get power trim. I understand I will have to enlarge the cutout in the transom, and may have to move the engines forward a little?

Finally the 270 outdrives I have shift nice and turn smoothly so I'm thinking the internals are good. If I were to buy a V6 or 4Cyl SP drive woud the gearsets from the lower housing in my 270 work in the SP case? just a thought as I have found more 4 and 6 cyl SPs than 8 cyl ones locally, and it was just a thought. Either way I plan on tearing down whatever drives I get to make sure everything is n working order before I install them in the boat. Thanks Murf

Warning if you are squeamish dont look at these pics!