drobertsobx

Member

New day new problem I think...

Both Heads completely descaled.

Both head gaskets replaced and heads torqued to 20 ft/lbs on the bench.

I have not retorqued the heads yet after the run gonna wait till morning.

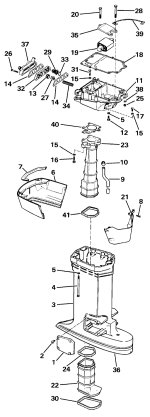

I installed the motor to the outboard exhaust housing, torqued everything to spec...

I Used a chain hoist, everything went smooth as silk no hang-ups or

alignment issues slipped right on down smooth onto the drive spline. zero issues.

Hooked all electrical back up.

Primed her up, and she started right up on second attempt. Ran idle up to 1200 RPM

to test for overheat.

First thing I noticed I wasn't getting any water blown out of the two

exhaust holes (Last time run, it was spitting water not a ton but some onto my legs) just before the over heat issue.

The temp started rising on the top of the starboard side head first... not to an overheat but

warmer than I was expecting.

Starboard side (160-174+- Top of head): cycling with the thermostats. SEEMS HIGH for a fast idle

Port side was cycling at (150-160+- Top of head)

Both bottoms in the 140's at the overheat sensors.

Telltale water cold throughout testing.

I felt comfortable enough with the overheat issue I started looking around for leaks

or anything that didn't look right on the entire motor.

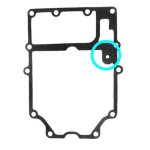

There is a bunch of water running out of the front area below the stud and bolt

for the exhaust housing on the starboard side, not from the base gasket and seems to be spun up

with the shaft. I never even looked up there on the initial run as it overheated so fast.

all my attention was with the laser on the heads.

Almost at my limit on this motor...

Can anyone hazard a guess as to what this is and if it is a problem, doesn't seem right to me?

Both Heads completely descaled.

Both head gaskets replaced and heads torqued to 20 ft/lbs on the bench.

I have not retorqued the heads yet after the run gonna wait till morning.

I installed the motor to the outboard exhaust housing, torqued everything to spec...

I Used a chain hoist, everything went smooth as silk no hang-ups or

alignment issues slipped right on down smooth onto the drive spline. zero issues.

Hooked all electrical back up.

Primed her up, and she started right up on second attempt. Ran idle up to 1200 RPM

to test for overheat.

First thing I noticed I wasn't getting any water blown out of the two

exhaust holes (Last time run, it was spitting water not a ton but some onto my legs) just before the over heat issue.

The temp started rising on the top of the starboard side head first... not to an overheat but

warmer than I was expecting.

Starboard side (160-174+- Top of head): cycling with the thermostats. SEEMS HIGH for a fast idle

Port side was cycling at (150-160+- Top of head)

Both bottoms in the 140's at the overheat sensors.

Telltale water cold throughout testing.

I felt comfortable enough with the overheat issue I started looking around for leaks

or anything that didn't look right on the entire motor.

There is a bunch of water running out of the front area below the stud and bolt

for the exhaust housing on the starboard side, not from the base gasket and seems to be spun up

with the shaft. I never even looked up there on the initial run as it overheated so fast.

all my attention was with the laser on the heads.

Almost at my limit on this motor...

Can anyone hazard a guess as to what this is and if it is a problem, doesn't seem right to me?