MCM (Sterndrive) Model MCM 4.3L ALPHA /BRAVO

MCM 4.3LH ALPHA / BRAVO

MCM 4.3L EFI ALPHA /BRAVO

Propshaft Horsepower

(SAV1 Rating)

190 205 (190)2 2101 (188)2

Propshaft Kilowatts (SAV1 Rating) 142 153 (142)2 1571 (146)2

Number of Cylinders V-6

Displacement 262 cid (4.3 l)

Bore / Stroke - in. (mm) 4.0 x 3.48 (101.6 x 88.4)

Compression Ratio 9.4:1 9.4:1

Compression Pressure Minimum 100 psi (690 kPa)7

Idle rpm In Neutral3 650 rpm5 600 rpm5

Maximum rpm (at WOT)3 4400-4800 rpm

Oil Pressure (at 2000 rpm) Minimum 30 psi (207 kPa)

Minimum Oil Pressure (at Idle) Minimum 4 psi (28 kPa)

Fuel Pressure (1800 rpm) 3-7 psi (21-48 kPa) 30 psi ( kPa)

Electrical System 12 V Negative (–) Ground

Alternator Rating 55 or 65 amp 8

Minimum Battery Requirements 375 cca / 475 mca / 90 Ah

Firing Order 1-6-5-4-3-2

Spark Plug Type

AC - MR43LTS

Champion - RS12YC

NGK - BPR6EFS

Spark Plug Gap .045 in. (1.1 mm)

Timing (at idle rpm)4 10° BTDC 8° BTDC

Preliminary Idle Mixture 1 1/4 Turns DNA

Thermostat 160° F (71° C)

Notes:

1 Power Rated in Accordance with NMMA (National Marine Manufacturers’ Association) rating procedures.

2 Power Rated in Accordance with SAV1 rating procedures. This rating procedure is used to certify that the

engine complies with “Stage 1” Bodensee and Swiss Regulations. Horsepower differences shown result from

differences in test rpm, allowable test tolerances, and/or installation of special kit components.

3 Measured using an accurate service tachometer with engine at normal operating temperature.

4 Timing must be set using a special procedure as outlined in the appropriate section of this manual. Timing cannot

be properly set using the conventional method.

5 A special procedure must be followed to adjust idle rpm. Consult your Authorized Mercury MerCruiser Dealer

before attempting this procedure.

6 Idle speed on EFI models is not adjustable.

7 Minimum recorded compression in any one cylinder should not be less than 70 percent of the highest recorded

cylinder.

8 Serial Number Break for 65 Amp alternator: OL619083 and above.

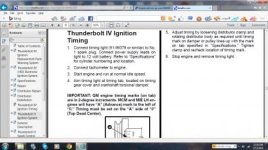

Setting Base Ignition Timing

1. Connect timing light (91-99379 or similar) to No. 1 spark plug wire. Connect power

supply leads, if applicable, on light to 12 volt battery.

2. Connect a shop tachometer to engine.

3. Using a jumper wire, connect the ignition system timing lead (PUR/WHT wire) to a good

engine ground (–). This locks the ignition module into the Base Timing Mode.

NOTE: Before starting engine make sure the timing tab and marks on damper are clean.

Chalk or white paint on timing marks may help visibility.

4. Start engine and run at normal idle speed. Allow engine to reach normal operating

temperature.

5. Aim timing light at timing tab, located on the timing gear cover and crankshaft torsional

damper.

6. If adjustment is required, adjust timing by loosening distributor clamp and rotating

distributor body as required until timing mark on damper or pulley lines up with the mark

on tab specified in “Specifications.” Tighten clamp and recheck location of timing mark.

7. Make sure that the distributor has been tightened. Remove the jumper wire from the

timing terminal.

8. Remove jumper wire between the timing lead (PUR/WHT wire) and ground (–).

IMPORTANT: Be sure to disconnect the jumper wire from between the ignition system

timing lead and ground (–) before attempting to resume normal operations. If the

jumper wire is left in place, the ignition module will operate in the Base Timing Mode.

This means that the additional timing advance features would not function.

9. Stop engine and remove timing light.

Model 4.3L / 4.3LH 4.3L EFI

Spark Plug Gap .045 in. (1.1 mm)

Spark Plug Type

AC-MR43LTS

NGK-BPR6EFS

Champion RS12YC

Acceleration Spark Advance

This feature is active during acceleration only. When accelerating, the ignition module may

add more spark advance to the “Base Spark Timing Curve”. The amount of spark advance

added, is totally dependant on how fast rpm increases (how fast the throttle is moved). This

feature is also active within a certain rpm range. This range may be slightly different from

one engine model to another. The approximate rpm range for this feature is 1200-4000 rpm.

Within this range, the module can add approximately 10 degrees of spark advance to the

base spark timing curve.

Mean-Best-Timing (MBT) Spark Advance

During light load cruising, the ignition module searches for the optimal ignition timing. This

is also accomplished by small changes to the spark advance. At a given rpm, the module

will try to add a small amount of advance and wait to see if there is an rpm change. If rpm

increases, it will try to increase timing more. The module will continue to advance timing until

it no longer gets an increase in rpm. Conversely, if it senses an rpm drop, it will start to retard

some of the spark timing. The approximate rpm range for this feature is 1200-4000 rpm.

Within this range, the ignition module can add approximately 10-15 degrees of spark

advance to the base spark timing curve.

NOTE: The Audio Warning System is also connected into the ignition module circuit. If the

audio warning system becomes activated by the closing of one of the audio warning system

switches, the MBT feature is deactivated.

Over-Speed Control

The ignition module will prevent the engine speed from exceeding a preset limit by stopping

the spark. This feature has an rpm range that varies from model to model. The over-speed

limit for a particular engine is set slightly higher than the top end of the rpm range for that

model. For example, if the recommended range is 4600-5000 rpm, the over-speed limit

would be set at 5100 rpm. When rpm reaches this limit, spark is turned-off until engine rpm

drops down to a “Reset rpm”, which would be approximately 4750 rpm for this example. At

this point, spark comes back on.

Knock Retard Spark Control

The knock control feature helps provide protection from harmful detonation. Knock control

is handled by the Knock Control Module. This module receives a signal from a sensor that

is mounted on the engine block. The knock control module works in conjunction with the

ignition module to retard the timing if spark knock is present.

IMPORTANT: The graph below shows the typical advance ranges for a Thunderbolt

V ignition control module. The numbers plotted on the graph are not representative

of any particular model. It is only presented to provide an understanding of how the

system functions.

Based on the timing graph in the manual with a base timing of 0 you should reach max timing 25 degrees before top dead center +/- 10 degrees by 1800 rpms.

The + is (Acceleration advance range) and ( MTB mean best timing)

The - would be (knock control spark range) meaning if a knock is sensed by the knock sensor the timing will retard up to 10 degrees or so.

so if base is set to 8 BTDC then max should be 33 btdc at or by 1800 rpms if no knock is detected.

= Base Timing Advance Curve

= Idle Speed Advance Range

= Knock Retard Range

= Acceleration Advance Range

= MBT Advance Range