Hi guys , i need some help in determining what is the problem with the following:

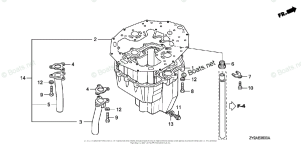

I owe a Honda BF200 , and recently experienced a continuous beep and temp symbol appeared on display. I have replaced impeller , both thermostats , cleaned both manifolds and still the same problem. Water is flowing good from pee hole. Also removed lower unit and fed a hose directly in pipe with good flow and pressure . Still overheating. Water came out good from thermostats ports. Noted that the starboard manifold is quite hotter than the other. Tried to flush from flush valve and noted that water was not flowing and thaught that there was a flush valve faulty but tried to put compressed air in the elbow after the flush valve and seems blocked. When on idle fault come out after 15mins and when rev or load it will come shorty in 1 to 3 minutes. I am thinking of a blocked passage/water jacket or a stuck poppet valve.? Anyone had this issue before ?

Thanks

I owe a Honda BF200 , and recently experienced a continuous beep and temp symbol appeared on display. I have replaced impeller , both thermostats , cleaned both manifolds and still the same problem. Water is flowing good from pee hole. Also removed lower unit and fed a hose directly in pipe with good flow and pressure . Still overheating. Water came out good from thermostats ports. Noted that the starboard manifold is quite hotter than the other. Tried to flush from flush valve and noted that water was not flowing and thaught that there was a flush valve faulty but tried to put compressed air in the elbow after the flush valve and seems blocked. When on idle fault come out after 15mins and when rev or load it will come shorty in 1 to 3 minutes. I am thinking of a blocked passage/water jacket or a stuck poppet valve.? Anyone had this issue before ?

Thanks