Alternator Tips

| CSS Drop Down Menu by PureCSSMenu.com | < Previous Page|Next Page > |

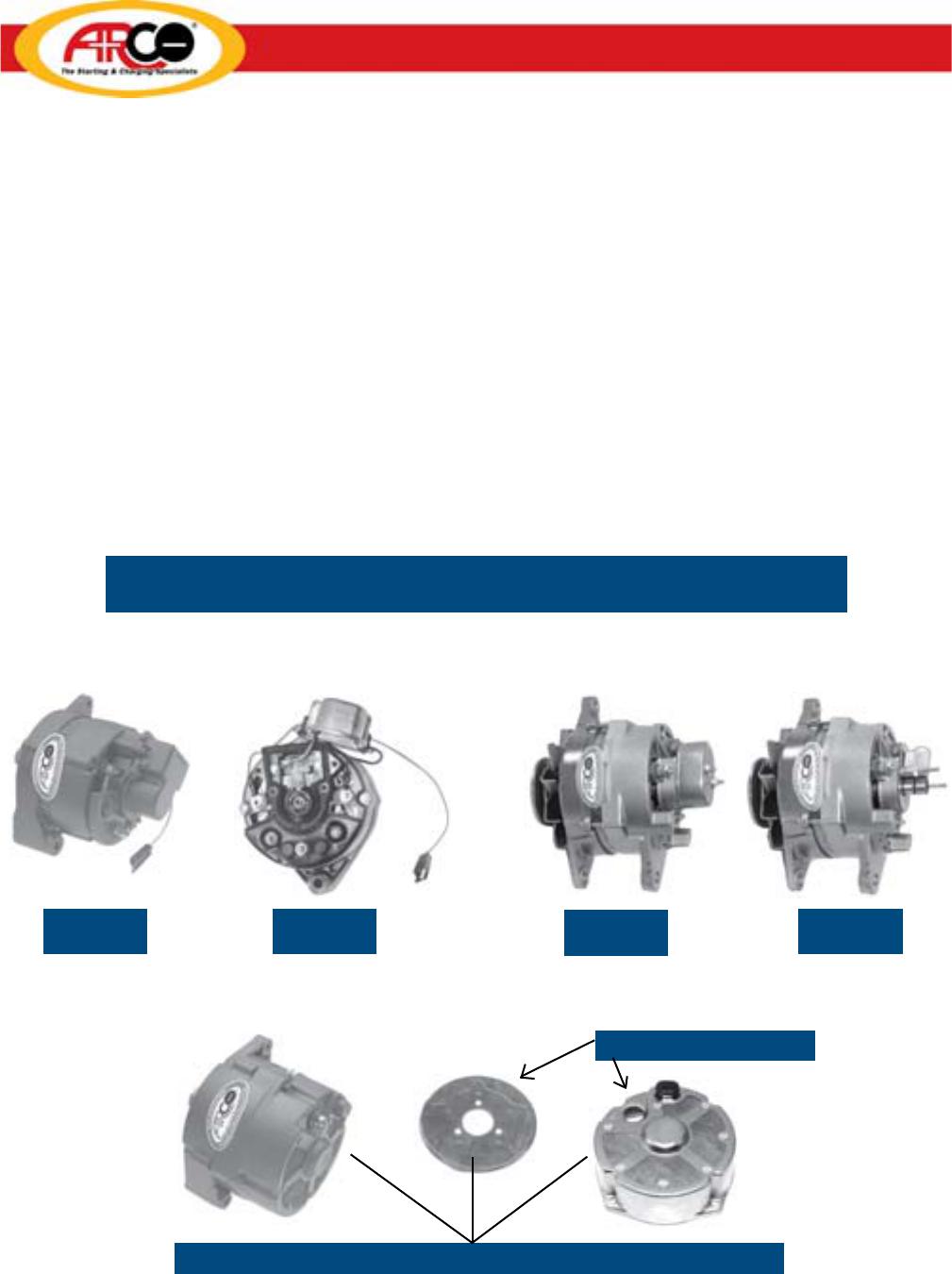

VARIOUS MARINE APPROVED ALTERNATOR DESIGNS

Brush Cover

Installed

Delco style alternators use flame arrestors instead of sealed brush compartments.

Alternators that are being installed on inboard gasoline engines must be certified to meet Coast Guard requirements for ignition

protection. In order for the alternator to be certified, it must pass the testing procedure, Marine SAE J1171, laid-out by the Society

of Automotive Engineers (SAE).

Brushes inside the alternator cause some sparking when the alternator is charging. This is normal for any alternator. When the

alternator is exposed to a flammable atmosphere, such as an enclosed engine compartment on an inboard gasoline application

with a fuel leak, the sparking from the brushes in the alternator may cause an explosion.

The Marine SAE J1171 testing procedure is as follows: A sparking device, similar to a spark plug, is installed in the brush area of

the alternator. Another device is also installed in the brush area of the alternator to supply a specified mixture of propane gas and

oxygen. The alternator is then placed in an explosion proof test chamber. The chamber and the alternator are then filled with the

explosive gas mixture. A high-voltage coil supplies current to the sparking device in the brush area of the alternator, causing an

explosion. An explosion must not occur in the test chamber while this test is being performed. This step is repeated nine times.

Finally, a spark is supplied inside the test chamber causing an explosion to ensure that the explosive mixture was present during

the testing operations.

ALTERNATORS APPROVED FOR MARINE USE

Motorola Style

Prestolite Style

Delco Style

Stainless steel 3-ply screens

Brush Cover

Installed

Brush Cover

Removed

Brush Cover

Removed

TECH TIPS