I recently finished rebuilding our worn out 1997 4.3 Mercruiser. Started with a rebuilt long block and swapped everything over.

I currently have the motor mounted on a pallet to test run it before putting in back in the boat. I have watched several YouTube videos but think I am missing something in the process.

Motor is fully dressed less throttle cable assembly and shift linkage assembly. I left these in the boat.

1997 Chaparral 1930SS, 4.3L Mercruiser Gen+, Thunderbolt V(?)

Setup:

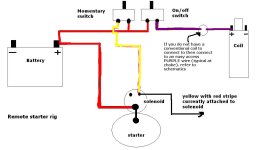

Battery + to Starter

Battery - to Engine Ground

Fuel from 2-gallon container through fuel-water filter

Jumper in wiring plug 5-6 (ignition on)

Jumper in wiring plug 6-7 (start)

When I touch 6-7, slave solenoid just clicks.

If I jump across slave solenoid, engine will turn over, but not start.

What is preventing me from engaging the starter by touching 6-7?

Thanks

I currently have the motor mounted on a pallet to test run it before putting in back in the boat. I have watched several YouTube videos but think I am missing something in the process.

Motor is fully dressed less throttle cable assembly and shift linkage assembly. I left these in the boat.

1997 Chaparral 1930SS, 4.3L Mercruiser Gen+, Thunderbolt V(?)

Setup:

Battery + to Starter

Battery - to Engine Ground

Fuel from 2-gallon container through fuel-water filter

Jumper in wiring plug 5-6 (ignition on)

Jumper in wiring plug 6-7 (start)

When I touch 6-7, slave solenoid just clicks.

If I jump across slave solenoid, engine will turn over, but not start.

What is preventing me from engaging the starter by touching 6-7?

Thanks