SlabSlayer

New member

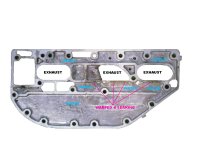

I have a '76 Johnson 70HP (70EL76D) that I inherited. It has been running for years with only a slight hesitation on WOT from neutral. Last season, it got worse to the point that the hesitation was permanent and it would not achieve more than 6 or 7 mph. I replaced the plugs and all 3 coils with CDI replacements in the offseason. This season, it began with the same. It would run cold off the dock, but once warmed up, it just wouldn't pull itself out of the water. I took it to one of the last remaining mechanics who would work on it and was told it had a blown power pack and one of the new CDI Coils was bad. He replaced both with used OEM. It ran better, but was still sick. After two outings it again wouldn't achieve more than a slow troll. I have pulled the flywheel, stator and timing ring look good. Replaced the power pack and all 3 coils with Johnson OEM New parts. When I was checking the wiring harnesses for possible rub shorts, I noticed a discrepancy in the Terminal Block Wiring. Not sure if it has always been this way or if my mechanic had some reason to change it. I tend to believe it has always been that way but the looks of it.

In the Seloc '73-'91 Johnson Outboards Repair Manual, Appendix p. A-18, it illustrates the yellow\gray wire from the Stator connected to Terminal 2 with the Gray wire from the Remote Control Assembly. However, on my Terminal Block, this wire is connected on Terminal 3 with the Yellow\Gray wire from the Rectifier & Lead Assembly.

Should I move it? Is this a normal variation in the wiring? What issues would present if left this way? Could that be a part of the problem? What might happen if I move it?

In the Seloc '73-'91 Johnson Outboards Repair Manual, Appendix p. A-18, it illustrates the yellow\gray wire from the Stator connected to Terminal 2 with the Gray wire from the Remote Control Assembly. However, on my Terminal Block, this wire is connected on Terminal 3 with the Yellow\Gray wire from the Rectifier & Lead Assembly.

Should I move it? Is this a normal variation in the wiring? What issues would present if left this way? Could that be a part of the problem? What might happen if I move it?