This is a new thread, former postings under "Johnson 1991 28 SPL Problem"

Regarding: Johnson 28 SPL 28SPLE28ESLCEA

with Electric Start

with Console Throttle / Warm Up Lever / Ignition and Choke

2 Cylinder, 2 Cycle

Use: Currently on 1971 Harris Flote Bote

Concern: Cannot get the engine to run consistently at High Speed and Low Speed at the same time.

Fuel: Non-Ethanol

50:1 2 cycle Oil Mixture

Tank: Clean, No Debris

No Vacuum Lock

Tank to Engine

Fuel Line: Good Condition, Line and Primer Bulb

Coupling to Fuel Pump

Fuel Line: New Fuel Line Added

In-Line Fuel Filter Added

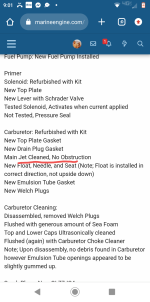

Fuel Pump: New Fuel Pump Installed

Primer

Solenoid: Refurbished with Kit

New Top Plate

New Lever with Schrader Valve

Tested Solenoid, Activates when current applied

Not Tested, Pressure Seal

Carburetor: Refurbished with Kit

New Top Plate Gasket

New Drain Plug Gasket

Main Jet Cleaned, No Obstruction

New Float, Needle, and Seat (Note; Float is installed in correct direction, not upside down)

New Emulsion Tube Gasket

New Welch Plugs

Carburetor Cleaning:

Disassembled, removed Welch Plugs

Flushed with generous amount of Sea Foam

Top and Lower Caps Ultrasonically cleaned

Flushed (again) with Carburetor Choke Cleaner

Note; Upon disassembly, no debris found in Carburetor however Emulsion Tube openings appeared to be slightly gummed up.

Spark Plugs: New QL77JC4

Gapped to 0.030"

Verified to Spark

Lower Housing: Fresh Gear Oil

Water Pump: Okay, good Water Flow

Limitations: No Service Manual

Not Checked: Timing

Cylinder Compression (required value unknown)

Fuel Pump Compression (should be 2 lbs / sq in?)

Ignition Points

Current Condition: Runs at High Speed briefly, then dies.

I cannot seem to get this engine to perform adequately at both Low and High Speed.

Most recently, I had this running well at low to mid-range throttle but then the engine would die when I attempted to run at high speed.

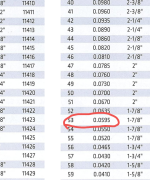

I took the carburetor back off and found that, while top position of Float was level as recommended.

The Float drop was at 0.8", so my assumption was that I had been starving the engine of fuel.

Now, with the Float drop at 1.3", the engine will only run briefly at high speed. Will not start without starting fluid.

It doesn't make any sense.

Carburetor Follower is set to dead center of Cam notches at low speed idle.

No High Speed Idle adjustment on this carb.

Low Speed Idle adjustment set to 1 1/2 turns counter-clockwise from close.

When the engine stops and I remove the Carburetor Plug, there is fuel in the carb, but when I remove the Spark Plugs they are dry.

There is no reason to suspect bad spark, timing, or compression...though those can't be ruled out since I haven't the equipment to test them. In any case, I don't know the what the proper values are.

I have followed all of the logical steps for tuning this engine, but success eludes me.

This has to be the something I'm doing wrong or overlooking with the Carburetor.

It has gone from fuel starvation to flooding to starvation again.

Any help / fresh ideas would be appreciated.

Photos upon request.

Regarding: Johnson 28 SPL 28SPLE28ESLCEA

with Electric Start

with Console Throttle / Warm Up Lever / Ignition and Choke

2 Cylinder, 2 Cycle

Use: Currently on 1971 Harris Flote Bote

Concern: Cannot get the engine to run consistently at High Speed and Low Speed at the same time.

Fuel: Non-Ethanol

50:1 2 cycle Oil Mixture

Tank: Clean, No Debris

No Vacuum Lock

Tank to Engine

Fuel Line: Good Condition, Line and Primer Bulb

Coupling to Fuel Pump

Fuel Line: New Fuel Line Added

In-Line Fuel Filter Added

Fuel Pump: New Fuel Pump Installed

Primer

Solenoid: Refurbished with Kit

New Top Plate

New Lever with Schrader Valve

Tested Solenoid, Activates when current applied

Not Tested, Pressure Seal

Carburetor: Refurbished with Kit

New Top Plate Gasket

New Drain Plug Gasket

Main Jet Cleaned, No Obstruction

New Float, Needle, and Seat (Note; Float is installed in correct direction, not upside down)

New Emulsion Tube Gasket

New Welch Plugs

Carburetor Cleaning:

Disassembled, removed Welch Plugs

Flushed with generous amount of Sea Foam

Top and Lower Caps Ultrasonically cleaned

Flushed (again) with Carburetor Choke Cleaner

Note; Upon disassembly, no debris found in Carburetor however Emulsion Tube openings appeared to be slightly gummed up.

Spark Plugs: New QL77JC4

Gapped to 0.030"

Verified to Spark

Lower Housing: Fresh Gear Oil

Water Pump: Okay, good Water Flow

Limitations: No Service Manual

Not Checked: Timing

Cylinder Compression (required value unknown)

Fuel Pump Compression (should be 2 lbs / sq in?)

Ignition Points

Current Condition: Runs at High Speed briefly, then dies.

I cannot seem to get this engine to perform adequately at both Low and High Speed.

Most recently, I had this running well at low to mid-range throttle but then the engine would die when I attempted to run at high speed.

I took the carburetor back off and found that, while top position of Float was level as recommended.

The Float drop was at 0.8", so my assumption was that I had been starving the engine of fuel.

Now, with the Float drop at 1.3", the engine will only run briefly at high speed. Will not start without starting fluid.

It doesn't make any sense.

Carburetor Follower is set to dead center of Cam notches at low speed idle.

No High Speed Idle adjustment on this carb.

Low Speed Idle adjustment set to 1 1/2 turns counter-clockwise from close.

When the engine stops and I remove the Carburetor Plug, there is fuel in the carb, but when I remove the Spark Plugs they are dry.

There is no reason to suspect bad spark, timing, or compression...though those can't be ruled out since I haven't the equipment to test them. In any case, I don't know the what the proper values are.

I have followed all of the logical steps for tuning this engine, but success eludes me.

This has to be the something I'm doing wrong or overlooking with the Carburetor.

It has gone from fuel starvation to flooding to starvation again.

Any help / fresh ideas would be appreciated.

Photos upon request.