captain_ed

Regular Contributor

Hello,

I am looking for a set of chrysler 440 heads with casting number 4006452. I will have them rebuilt. My e-mail is [email protected] (my name is Ed).

I had a miss in the engine. Upon checking..... I had no compression on #4 cylinder (reverse rotation motor). The center of the spark plug was missing???? The little "hook" was there ,but the center was gone. I pulled the heads and the pisons and cylinder walls look fine. The machine shop said that there are cracks around the spark plug holes? The valves looked sunken in also. They said that high cylinder temps or bad timing could be the cause. I had checked the timing and they are 5* BTDC. I appear to get 26* advance in the timing. Everything seemed O.K. with the timing. The plugs that came out were light tan in color. They did not appear to be too hot. I have new thermostats ,raw water pumps, heat exchangers, manifolds, risers, elbows etc.

Ideas??

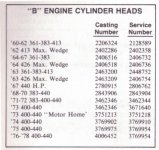

*another post mentioned heads with extra cooling passages??? What are the casting numbers for those??? Would they work on a stock 440 magnum marine engine?

Thanks,

Ed

I am looking for a set of chrysler 440 heads with casting number 4006452. I will have them rebuilt. My e-mail is [email protected] (my name is Ed).

I had a miss in the engine. Upon checking..... I had no compression on #4 cylinder (reverse rotation motor). The center of the spark plug was missing???? The little "hook" was there ,but the center was gone. I pulled the heads and the pisons and cylinder walls look fine. The machine shop said that there are cracks around the spark plug holes? The valves looked sunken in also. They said that high cylinder temps or bad timing could be the cause. I had checked the timing and they are 5* BTDC. I appear to get 26* advance in the timing. Everything seemed O.K. with the timing. The plugs that came out were light tan in color. They did not appear to be too hot. I have new thermostats ,raw water pumps, heat exchangers, manifolds, risers, elbows etc.

Ideas??

*another post mentioned heads with extra cooling passages??? What are the casting numbers for those??? Would they work on a stock 440 magnum marine engine?

Thanks,

Ed