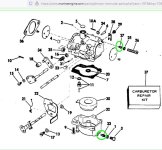

I have never been able to get this motor running properly at 8500 feet. Runs fine at idle but wants to stall when throttle advanced except if advanced very gently it will usually rev up to normal RPM. It will always rev up when in neutral but stalls as described when in gear (loaded). It always stalls if I try to drive it onto the trailer. A dealer sold me what was supposed to be high altitude jets a couple of years ago which I installed; little change in how it ran, no improvement in power. I removed those today and compared the orifice to the one in the original (sea level) jets and found that it (or rather they since this thing has three carbs) is larger than the sea level orifice. hmmm methinks that's the wrong direction!? I have also diddled around with the prop ie switched back to aluminum from SST to reduce weight, reduced prop pitch (but only slightly), made little if any difference. So the questions: (1) can anyone out there say whether this is a prop size/pitch issue, a high speed jet issue or both? Or for that matter is it something entirely different and if so what? (2) if a change in the prop size/pitch is recommended is there a scientific method to determine what size/pitch is called for or is it a matter of trial and error? (3) If it's a high speed jet issue does anyone know of a reliable source for high altitude jets? The parts lists I've found show only one jet, #68, which is the original in this motor to which I referred above as the "sea level" jet. Sorry to be so long winded on this but I've been screwing with this for way too long and I know there is a solution. Any and all ideas will be appreciated.

J O

J O

Last edited: