I saw my grandkid, too.

I put in the new 0-gauge cables, took out the spark plugs and spun the engine with the starter, and same slow crank!

I did it for 20 seconds for 7 or 8 times and it didn't speed up, just got slightly slower as the battery ran down. It did still crank at 12.3 before it got quite slow, which is better, and may just be attributable to no plugs, less resistance.

I went ahead and did a compression test, as it is really hard to get the p[ugs out with the GT40 heads and the oversized exhaust manifolds. The results were #1 - 70 psi, @2 - 80 psi, #3 - 70 psi, #4 - 70 psi, #5 - 90 psi, #6 - 90 psi, #7 - 92 psi, #8 - 65 psi.

This may not tell me anything, as the oil still may not be distributed throughout the engine, and any other variables, from the re-build but it is about a 30% variance.

So, I don't know if I got the oil pump primed - seems it should run faster, if I did. So assuming it is not primed, should I spin it through the distributer? I guess. Any other ways of telling? I don't want to take off the valve covers just to tell, as I would first have to take off the heavy oversized cast iron exhaust manifolds.

Other possibilities on the slow crank:

1. wrong starter. The last one did the same. It is for a 70's Ford 302 marine OMC, has nine tooth drive gear. Not sure if I have 157 or 164 tooth ring gear - I did count them once and it seemed it was over 160, as I recall, but not sure. This one says it is for a 157 tooth , and cost about $100. Is there any point in getting a $400 one? Maybe I should call marineengine,com and see if I can get the right one. This is from the one I have:

New Professional Grade Starter Compatible with Ford Marine & Crusader Various Mercruiser Stern Dri Model 888 1971-77 OMC 5.0L 5.8L Waukesha 302/351 1971-76 D5FF-11001-AA D8FF-11001-DA E1JF-11001-AA

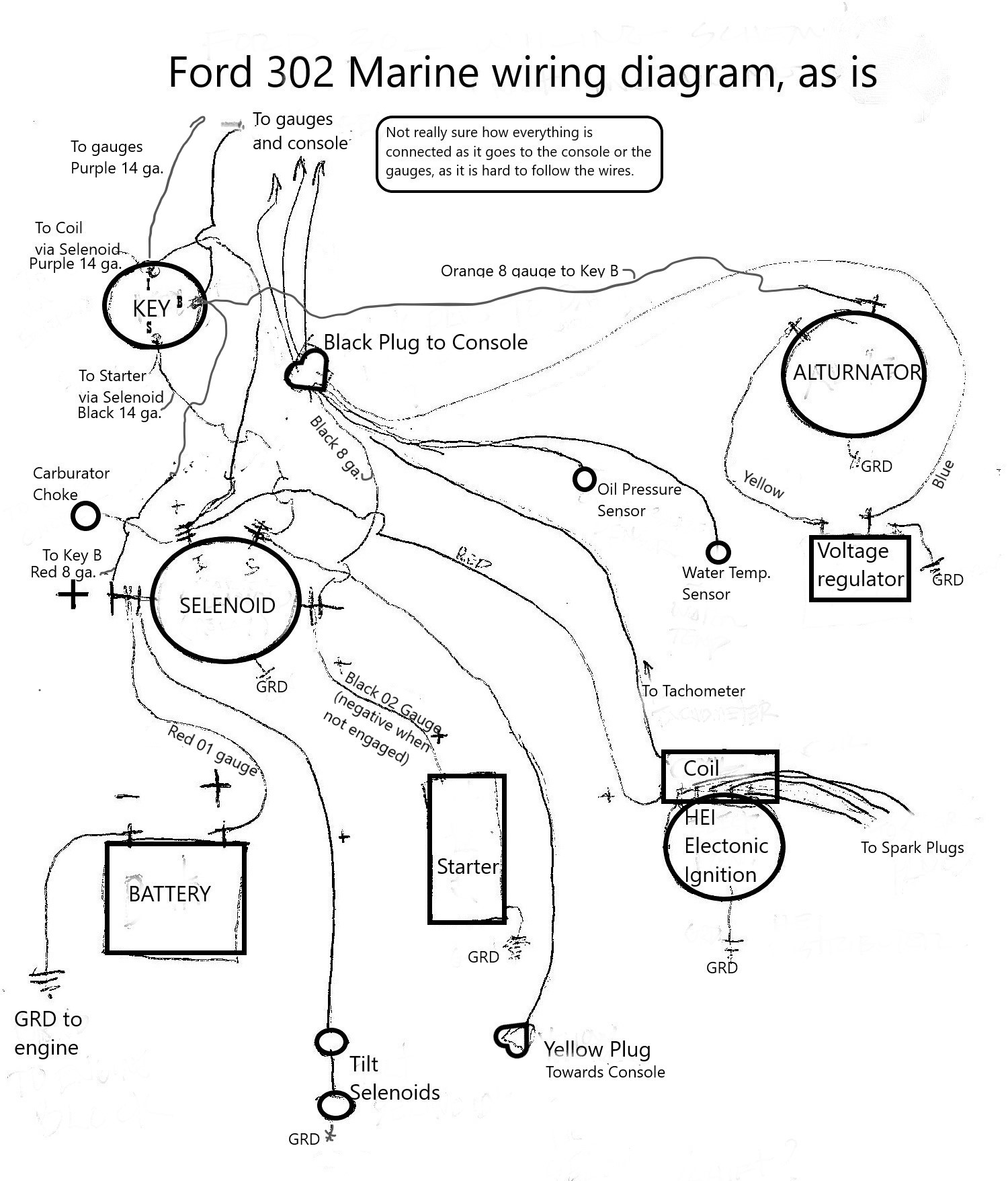

2. Still some electrical problem. I am waiting for the new wiring for beween the key and the selonoid. Could check the batteries again. I do have a tester that checks under load, as it has a little heater to simulate a load. They are both large and about a year and a half old AGM batteries. They do seem to fully charge to 13.6 volts, but do seem to rundown quickly. I have tried hooking up to my Ford F150 battery with the same results.

3. Some internal problem from the re-build, (worst case scenerio). I would have to finish off the oil pump priming and the other electrical, and perhaps the starter and anything else I could think of, as I have been the mechanic on putting everything back together from the raw re-built engine block. So it could be from other things I may have done wrong.

Any thoughts on how I should proceed? Or any thing else that may be awry?