markbabb

Contributing Member

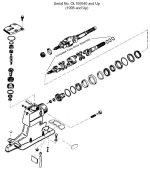

My Alpha one Gen 2 outdrive went south on me yesterday. Towed back and now that I am figuring out what went wrong. I took the cap off and roller bearing and shaft are just loose, as I am able to remove and see that it is sheared off. I see a picture in a diagram of the replacement shaft 45-55796-1 . My question is how is the bottom of the shaft which is still in the drive attached to the lower units shaft or the gear. It started raining on me so that gave me the chance to ask the forum if there is a better diagram, or can someone give me a written lesson on how to remove the broken piece of the shaft and how it works. Just waiting on the rain to stop and some help.

View attachment 15907

View attachment 15907