NorthernBeek

New member

Hello all,

I got a honda BF9.9A (late 1980's) with a sailboat I purchased. When it came time to hang the motor and get it in the water, the motor wouldn't start. Diagnosis showed the coil was dead (zero resistance, open circuit on the secondary coil). This is a 2-plug coil, so resistance is measured between the two sparkplug connectors. I even pulled plug wires off and tested at the coil. No continuity.

A new coil was ordered. It sat on the bench for a month while we used the sailboat with a different motor. I need to put the motor away for the winter, so I finally installed the new coil, the unit started fairly easily. Shut down and restarted a few times as I've got no water flow (spent a few minutes diagnosing that the telltale isn't plugged, time for a waterpump replacement). Head in to tell the wife the bad news, and when I come back out it won't start. No spark. Pull out the multimeter and sure enough there is open circuit on the secondary coil.

This new coil has run for 5 minutes and is dead. I anticipate the dealer not wanting to order any sort of warranty replacement. At $165Cdn before tax, I don't want to pay for another one without a clearer picture of what's going on!

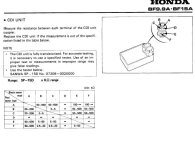

I'm too new, so I can't attach the wiring diagram for the motor... but it's fairly simple...

-exciter coil to power the CDI

-separate charge coil to the charging circuit (independent from the CDI system)

-cam pulser coil to signal CDI to spark

-oil pressure switch & light

-stop switch

Coil can't really be installed backwards; two wires, one is input, one is ground, there are no diodes or circuitry in the coil.

Has anyone ever experienced a replacement coil failing that quickly?

Could the CDI unit somehow be frying the coil?

Suggestions?

I got a honda BF9.9A (late 1980's) with a sailboat I purchased. When it came time to hang the motor and get it in the water, the motor wouldn't start. Diagnosis showed the coil was dead (zero resistance, open circuit on the secondary coil). This is a 2-plug coil, so resistance is measured between the two sparkplug connectors. I even pulled plug wires off and tested at the coil. No continuity.

A new coil was ordered. It sat on the bench for a month while we used the sailboat with a different motor. I need to put the motor away for the winter, so I finally installed the new coil, the unit started fairly easily. Shut down and restarted a few times as I've got no water flow (spent a few minutes diagnosing that the telltale isn't plugged, time for a waterpump replacement). Head in to tell the wife the bad news, and when I come back out it won't start. No spark. Pull out the multimeter and sure enough there is open circuit on the secondary coil.

This new coil has run for 5 minutes and is dead. I anticipate the dealer not wanting to order any sort of warranty replacement. At $165Cdn before tax, I don't want to pay for another one without a clearer picture of what's going on!

I'm too new, so I can't attach the wiring diagram for the motor... but it's fairly simple...

-exciter coil to power the CDI

-separate charge coil to the charging circuit (independent from the CDI system)

-cam pulser coil to signal CDI to spark

-oil pressure switch & light

-stop switch

Coil can't really be installed backwards; two wires, one is input, one is ground, there are no diodes or circuitry in the coil.

Has anyone ever experienced a replacement coil failing that quickly?

Could the CDI unit somehow be frying the coil?

Suggestions?