Pulled the Mercruiser 2.5L engine for a rebuild and decided to check the wood under the engine mount and found mush. Not sure what wood it is, as it was leaching black water back into the bilge it may have been a railroad tie? Pic below, had to handle it very gently not to have it come apart. Wish I had snapped a couple pics before removing it but didn't anticipate a issue with something as simple as this, surprise, surprise.

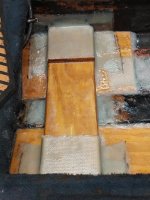

There was also some plywood under it that had rot, one on the port side all the way to the transom so I removed it and part of the starboard side until I found good wood. I then cut replacement pieces and built up a replacement for the railroad tie of laminated ply.

I glued up the support and epoxied all three pieces and installed the two pieces of ply. After I fill the gaps and throw a little fiberglass on the seamed piece, I'll be ready to install the beam. It was hard to tell but the one removed didn't appear to be glued down and had a nice piece of fiberglass securing it front to back. Must have been fairly strong as a 900lb. Mercruiser front feet were lagged into it with no help underneath. The beam wasn't seemingly sealed at all, just raw wood.

Now my questions, first, what is that support called? My burning question is how di I install the new support? Do I glue or epoxy the bottom to the replaced ply? Do I use some lesser holding adhesive (in case it ever needs to come out) like PL375 or Premium to fill in any voids and fiberglass it down? I did widen my replacement so I could fiberglass it to the stringers as well. The old one was 2" shy from them and was only glassed in front to back. Do I only lay glass from the top to the floor and sides and let it float?

I've spent hours searching with very limited success and nothing definitive. I'm a newbie to boating but generally can figure things out but this has me stumped.

Thanks

Bill

There was also some plywood under it that had rot, one on the port side all the way to the transom so I removed it and part of the starboard side until I found good wood. I then cut replacement pieces and built up a replacement for the railroad tie of laminated ply.

I glued up the support and epoxied all three pieces and installed the two pieces of ply. After I fill the gaps and throw a little fiberglass on the seamed piece, I'll be ready to install the beam. It was hard to tell but the one removed didn't appear to be glued down and had a nice piece of fiberglass securing it front to back. Must have been fairly strong as a 900lb. Mercruiser front feet were lagged into it with no help underneath. The beam wasn't seemingly sealed at all, just raw wood.

Now my questions, first, what is that support called? My burning question is how di I install the new support? Do I glue or epoxy the bottom to the replaced ply? Do I use some lesser holding adhesive (in case it ever needs to come out) like PL375 or Premium to fill in any voids and fiberglass it down? I did widen my replacement so I could fiberglass it to the stringers as well. The old one was 2" shy from them and was only glassed in front to back. Do I only lay glass from the top to the floor and sides and let it float?

I've spent hours searching with very limited success and nothing definitive. I'm a newbie to boating but generally can figure things out but this has me stumped.

Thanks

Bill