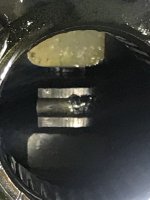

2 years ago. just a clanging in reverse. Shift dog cracked. New dog from marineenging.com (listed as merc part) I finished that year and went a few times last year.

First trip this year... same thing happened. I don't shift hard, and I don't force it without engine running. Oil was changed b4 trip. Is there something that could be causing this?

First trip this year... same thing happened. I don't shift hard, and I don't force it without engine running. Oil was changed b4 trip. Is there something that could be causing this?