Magonsterz

New member

Engine serial number 0L373392

Merc 7.4 mpi 2000 2855 Ciera SUN BRIDGE approx 300 hrs on engine.

Started missing, out of the blue, had been a while since tune up so replaced rotor and cap (showed corrosion) still has miss.

Pulled plugs and port side plugs looked to be covered in black soot but dry starboard side plugs were correct cocoa brown color. Wire brushed, hit with brake clean, gapped to .045, reinstalled. Plan to replace with new.

Replaced plug wires with new, even swapped in new fuel/water separator filter, ran better but still missed, just less.

Had new ignition module and dist coil pick up and ignition coil from previous project build, swapped in and set timing to 8degress, starts right up, comes up to temp 170 on gauge cluster, idles and revs just fine but still has intermittent miss regardless of at idle or up in the rpm, still sooting up all port side 1, 3, 5 & 7 plugs only.

Figured best to check for codes at this point, came up with code 14, "Engine Coolant Temperature (ECT)" so going to run the traps on Sensor and Sensor Circuit - Low Temperature Indicator testing procedure unless any one has different advice for me.

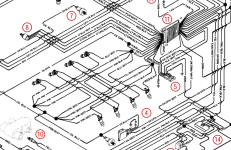

Using Merc service manual Number 23 pages 783-785

https://d3gqux9sl0z33u.cloudfront.ne..._8.2_litre.pdf

Merc 7.4 mpi 2000 2855 Ciera SUN BRIDGE approx 300 hrs on engine.

Started missing, out of the blue, had been a while since tune up so replaced rotor and cap (showed corrosion) still has miss.

Pulled plugs and port side plugs looked to be covered in black soot but dry starboard side plugs were correct cocoa brown color. Wire brushed, hit with brake clean, gapped to .045, reinstalled. Plan to replace with new.

Replaced plug wires with new, even swapped in new fuel/water separator filter, ran better but still missed, just less.

Had new ignition module and dist coil pick up and ignition coil from previous project build, swapped in and set timing to 8degress, starts right up, comes up to temp 170 on gauge cluster, idles and revs just fine but still has intermittent miss regardless of at idle or up in the rpm, still sooting up all port side 1, 3, 5 & 7 plugs only.

Figured best to check for codes at this point, came up with code 14, "Engine Coolant Temperature (ECT)" so going to run the traps on Sensor and Sensor Circuit - Low Temperature Indicator testing procedure unless any one has different advice for me.

Using Merc service manual Number 23 pages 783-785

https://d3gqux9sl0z33u.cloudfront.ne..._8.2_litre.pdf