Killerbean

Member

Hello Again !

3 weeks later and i have use the engine for more then 40km (25miles).

Technically the engine runs perfect.

Oil light is working and after the oil change the light lid up after 2 seconds because the oil filter had to be filled.

So the system actually works that is very nice to know.

Also i have serviced the complete engine with all the original honda parts.

It runs on first or second pull.

Thank you for your tips and tricks, and yes, i agree to see that honda is very reliable and simple to work on.

The other day my friend had a little overheating problem with his new suzuki 30hp. The engine went to 'emergancy run' (dont know what its called)

He had to go to the dealer to reset the system. Also i personally dont like the injection system yet. Easy and simple is what i like

btw i didnt burn my hand on the pee stream, but yes it was hot indeed hahah.

Okay now i have another question wich i hope can have an easy fix this time.

Engine runs perfect.

It is used on a cheap rubberboat, i think you guys call it a SIB. It has a removable aluminium floor.

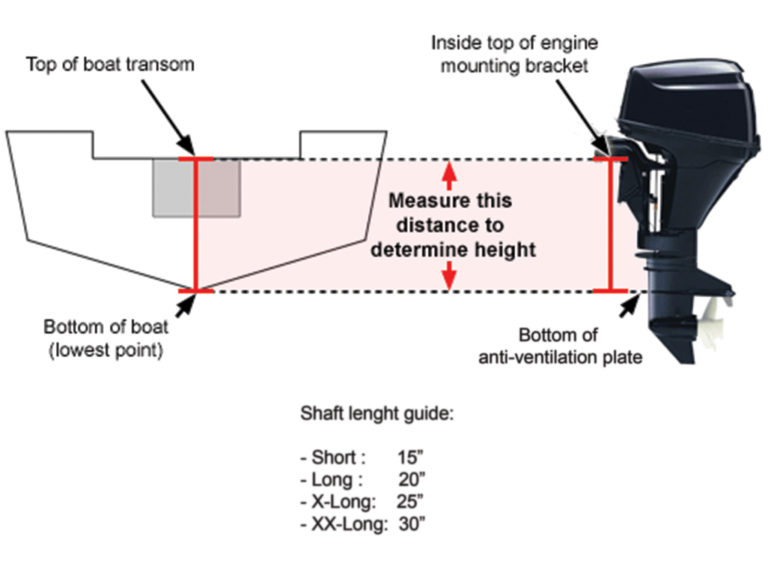

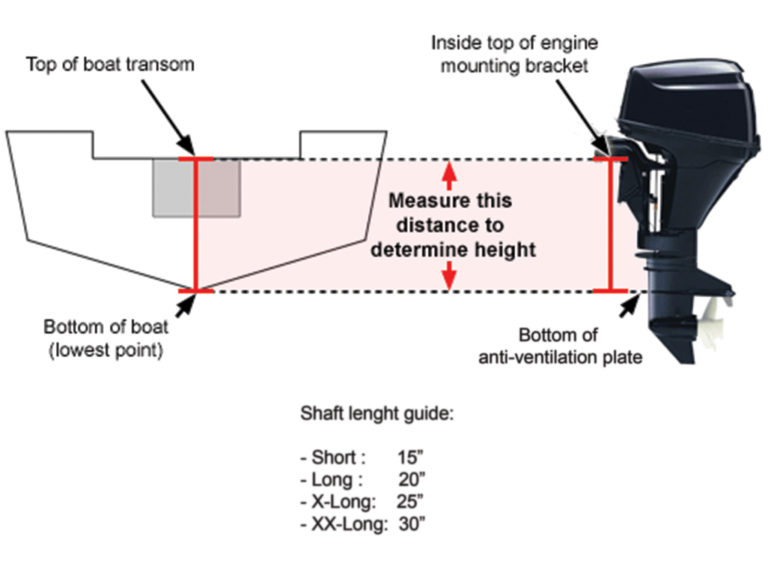

The transom height is 15 inch / 38cm

the outboard height from mounting arm to cavitation plate is 17.3 inch / 43.3mm

As far as i know the cavitation plate should be on the same level of the transom lowest point

My speed without any adjustments is 34km/h - 21 mp/h.

Without adjustments, the lower end of the engine makes backwash, it throws a lot of water back in the boat.

I have ordered and installed a 3 cm / 1.18 inch stainless steel bracket to elevate the engine a little bit.

if possible i dont want to go any higher because the clamps of the engine are near the top of the official transom (the actual wood)

With this higher engine the topspeed is the same. But the backwash is over. No more backwash.

When the engine is trimmed in the most upper position (furthest from trnasom) the engine takes air

When the engine is trimmed in the most down position (closest to transom) there is a very little bit backwash.

Basically it is all fine now.

But..... i really would like to have a little bit more speed.

I used to have a honda 8hp on the same boat wich did go 28km/h - 17.3mp/h

The difference in speed between 8 and 15hp is just too small in my opinion.

Today i have sailed together with another person. He had the a slight smaller boat (suzumar 340) with a B brand 9,9hp (Hallmarine).

We did have the exact same speed. I think that i should be faster with the 15hp. yes i know it depends on a lot of factors but all in all i think at this moment my outboard underpreforms.

My questions:

Is it better to make a new and bigger stainless steel bracket wich makes the engine even higher in the water.

I have the original 4 blade prop on the engine now. Some people tell me this is working prop for bigger vessels. Any idea's?

I will post photo's and video's below

The prop that is on now is 9-1/4 x 10

4 blade

3 weeks later and i have use the engine for more then 40km (25miles).

Technically the engine runs perfect.

Oil light is working and after the oil change the light lid up after 2 seconds because the oil filter had to be filled.

So the system actually works that is very nice to know.

Also i have serviced the complete engine with all the original honda parts.

It runs on first or second pull.

Thank you for your tips and tricks, and yes, i agree to see that honda is very reliable and simple to work on.

The other day my friend had a little overheating problem with his new suzuki 30hp. The engine went to 'emergancy run' (dont know what its called)

He had to go to the dealer to reset the system. Also i personally dont like the injection system yet. Easy and simple is what i like

btw i didnt burn my hand on the pee stream, but yes it was hot indeed hahah.

Okay now i have another question wich i hope can have an easy fix this time.

Engine runs perfect.

It is used on a cheap rubberboat, i think you guys call it a SIB. It has a removable aluminium floor.

The transom height is 15 inch / 38cm

the outboard height from mounting arm to cavitation plate is 17.3 inch / 43.3mm

As far as i know the cavitation plate should be on the same level of the transom lowest point

My speed without any adjustments is 34km/h - 21 mp/h.

Without adjustments, the lower end of the engine makes backwash, it throws a lot of water back in the boat.

I have ordered and installed a 3 cm / 1.18 inch stainless steel bracket to elevate the engine a little bit.

if possible i dont want to go any higher because the clamps of the engine are near the top of the official transom (the actual wood)

With this higher engine the topspeed is the same. But the backwash is over. No more backwash.

When the engine is trimmed in the most upper position (furthest from trnasom) the engine takes air

When the engine is trimmed in the most down position (closest to transom) there is a very little bit backwash.

Basically it is all fine now.

But..... i really would like to have a little bit more speed.

I used to have a honda 8hp on the same boat wich did go 28km/h - 17.3mp/h

The difference in speed between 8 and 15hp is just too small in my opinion.

Today i have sailed together with another person. He had the a slight smaller boat (suzumar 340) with a B brand 9,9hp (Hallmarine).

We did have the exact same speed. I think that i should be faster with the 15hp. yes i know it depends on a lot of factors but all in all i think at this moment my outboard underpreforms.

My questions:

Is it better to make a new and bigger stainless steel bracket wich makes the engine even higher in the water.

I have the original 4 blade prop on the engine now. Some people tell me this is working prop for bigger vessels. Any idea's?

I will post photo's and video's below

The prop that is on now is 9-1/4 x 10

4 blade

Last edited: