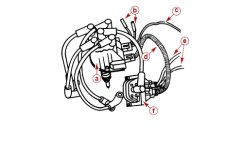

Hello Boater’s, I recently bought a 1999 Stingray/mercruiser 3.0 in good running conditions but needed a floor replacement. I decided to pull the engine and replace every single gasket, oil pan gasket, head gasket, oil seal, carb kit, etc.. Inspect every single wire, connection, etc.. Long story short, I have the engine ready to put back in the boat, but want to bench tested to make sure there no leaks, here is my problem. I have 12.5 volt everywhere, on the starter, on the solenoid when switch is on the on position, on the purple wire at the coil, on the plug going to the distributor, also have spark on the coil wire but not spark at all to the spark plugs. in a nutshell, I have spark going into the distributor but is not coming out to the spark plugs, I took the cap and rotor out, test for 12v on the ignition module and it has 12v when switch is on (not sure if that mean is good) also had triple check the timing, every single time #1 piston TDC on the compression stroke, rotor facing #1 wire, etc.. also 210psi in each cylinder. Not sure what to do next. Need help

Home

Outboard Motor Parts

Chrysler outboard parts Evinrude outboard parts Force outboard parts Honda outboard parts Johnson outboard parts Mariner outboard parts Mercury outboard parts Suzuki outboard parts Tohatsu outboard parts Yamaha outboard partsInboard & Sterndrive Engine Parts

Chrysler Marine inboard parts Crusader Marine parts MerCruiser sterndrive parts OMC sterndrive parts Pleasurecraft Marine parts Volvo Penta marine parts + MoreAll Engine Brands

All Manuals HomeOutboard Repair Manuals

Chrysler outboard manuals Evinrude outboard manuals Force outboard manuals Honda outboard manuals Johnson outboard manuals Mariner outboard manualsMercury outboard manuals Nissan outboard manuals Suzuki outboard manuals Tohatsu outboard manuals Yamaha outboard manuals

Inboard & Sterndrive Engine Manuals

MerCruiser sterndrive manuals OMC sterndrive manuals Volvo Penta marine engine manualsPlease Note

MarineEngine.com does not offer troubleshooting assistance or repair advice by email or by telephone.

You are invited to join our public Boat Repair Forum to seek assistance from other members.

You may also visit the Boat Motor Manuals section of our site to obtain a service manual.