Hello to All,

As the senior member of our boating family, I was recently tasked with bringing back to life an old “Turtle”, MQ-11C. By inspection, this motor has lived a rough life, with about the only good things going for it when it arrived at my workshop being that it was not seized and had good compression (75 lbs. ea.).

The next thing I did was test for spark…only one plug wire was hot. I removed the flywheel and found one seemingly “original” coil and the other being a Sierra replacement. Interestingly enough, it was the Sierra coil that showed no spark. After removing this coil, I noticed that the HV wire end was heavily corroded. I snipped off about an inch of this wire, reinstalled the coil, and retested for spark. Both coils then tested good. Disclaimer – I don’t have a “spark jump tool” I have a plug-in tool that lights up when spark is present. It hasn’t failed me in the past on prior OB rebuild projects.

Feeling pretty good about the coils, I decided to go ahead and get some new parts coming. I ordered a new carb kit, tune-up kit, impeller, and T-Stat. I removed the old parts and installed these new ones without incident. Then, with freshly mixed gas on hand, I placed the motor in my test tank and began pulling….no luck….then after a squirt of starting fluid, she roared to life. Following several stops and starts, I was able to keep her running long enough to warm up. My hope was, after warming up she would “smooth out” and allow me to fine tune the low-speed jet adjustment…no luck….she never smoothed out….lots of coughing and sputtering, every time I attempted to slow her down this happened.

Having read many articles on this forum and others, I thought it may be helpful to provide you a bit more specifics as to exactly what I did in performing the repair work. First, the points were set to 20 with a feeler gauge and, as per J. Reeves, a size 22 would not pass through. The points were brand new and cleaned. The carb was completely disassembled, thoroughly cleaned (every orifice), and then reassembled with new parts and gaskets per kit. The initial setting of the low-speed jet was 1.5 turns out after first gently seating. The water in the test tank was well above the water pump and the exhaust contained plenty of water (not an overheating issue). The motor cowling was left off, eliminating the possibility of exhaust backfeed.

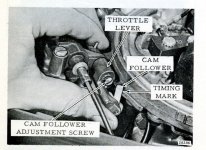

So, what’s your thoughts as to where I should begin a “deep dive”? Carburetor? Ignition? If so, where? I’m leaning toward this being a fuel issue, as she really comes to life with the starting fluid. One other disclaimer – how big of a deal is the “synchronizing fuel and ignition” adjustment? Quite honestly, it’s not very well written in the manual and I can’t say for sure I understand what they are trying to get across with “center of the mark”. What mark? I can sure see where the throttle first begins to move, but how do you correlate this with “a mark”? Could this lone adjustment be the entire source of my difficulties here? I’m thinking not, but would sure appreciate more guidance as to how this “synchronization” is supposed to work on this little 9.5 Turtle.

Thanks in advance for your feedback!!!

As the senior member of our boating family, I was recently tasked with bringing back to life an old “Turtle”, MQ-11C. By inspection, this motor has lived a rough life, with about the only good things going for it when it arrived at my workshop being that it was not seized and had good compression (75 lbs. ea.).

The next thing I did was test for spark…only one plug wire was hot. I removed the flywheel and found one seemingly “original” coil and the other being a Sierra replacement. Interestingly enough, it was the Sierra coil that showed no spark. After removing this coil, I noticed that the HV wire end was heavily corroded. I snipped off about an inch of this wire, reinstalled the coil, and retested for spark. Both coils then tested good. Disclaimer – I don’t have a “spark jump tool” I have a plug-in tool that lights up when spark is present. It hasn’t failed me in the past on prior OB rebuild projects.

Feeling pretty good about the coils, I decided to go ahead and get some new parts coming. I ordered a new carb kit, tune-up kit, impeller, and T-Stat. I removed the old parts and installed these new ones without incident. Then, with freshly mixed gas on hand, I placed the motor in my test tank and began pulling….no luck….then after a squirt of starting fluid, she roared to life. Following several stops and starts, I was able to keep her running long enough to warm up. My hope was, after warming up she would “smooth out” and allow me to fine tune the low-speed jet adjustment…no luck….she never smoothed out….lots of coughing and sputtering, every time I attempted to slow her down this happened.

Having read many articles on this forum and others, I thought it may be helpful to provide you a bit more specifics as to exactly what I did in performing the repair work. First, the points were set to 20 with a feeler gauge and, as per J. Reeves, a size 22 would not pass through. The points were brand new and cleaned. The carb was completely disassembled, thoroughly cleaned (every orifice), and then reassembled with new parts and gaskets per kit. The initial setting of the low-speed jet was 1.5 turns out after first gently seating. The water in the test tank was well above the water pump and the exhaust contained plenty of water (not an overheating issue). The motor cowling was left off, eliminating the possibility of exhaust backfeed.

So, what’s your thoughts as to where I should begin a “deep dive”? Carburetor? Ignition? If so, where? I’m leaning toward this being a fuel issue, as she really comes to life with the starting fluid. One other disclaimer – how big of a deal is the “synchronizing fuel and ignition” adjustment? Quite honestly, it’s not very well written in the manual and I can’t say for sure I understand what they are trying to get across with “center of the mark”. What mark? I can sure see where the throttle first begins to move, but how do you correlate this with “a mark”? Could this lone adjustment be the entire source of my difficulties here? I’m thinking not, but would sure appreciate more guidance as to how this “synchronization” is supposed to work on this little 9.5 Turtle.

Thanks in advance for your feedback!!!