Hi all,

I have a 1982 Johnson 60 hp 2 cylinder

I need to remove the head. I have noticed that the head also bolts to like engine mounts.

Question : when removing the head do I need to have something to support the block,,,,, Or just don't worry about it??

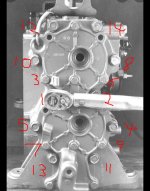

I can't seem to find the tightening sequence for the bolts. Google keeps coming up with different model johnson.

Thanks to all

I have a 1982 Johnson 60 hp 2 cylinder

I need to remove the head. I have noticed that the head also bolts to like engine mounts.

Question : when removing the head do I need to have something to support the block,,,,, Or just don't worry about it??

I can't seem to find the tightening sequence for the bolts. Google keeps coming up with different model johnson.

Thanks to all