I have been searching this forum and other internet sites and I can't find a definitive answer on how to flush the elbows (aka-risers) and manifolds on my 2005 Sea Ray 185 Sport (4.3l Alpha 1) while in the water and NOT using muffs. Biggest issue I believe is the Alpha 1 has the impeller in the outdrive.

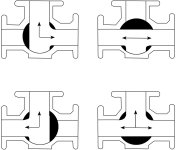

I'm new to boating and want to start next year flushing after every trip. My boat has a hose fitting on the swim deck that I tried to trace yesterday but being it's behind the motor I couldn't verify the exact routing. I could barely see that it leads into an off-white plastic housing and then splits to two hoses. One hose I could tell leads to the T-Stat housing and the other I'm assuming goes to the PS Cooler and then down to the Outdrive impeller, which would be the raw water supply during normal operation. The sketch I attached is what I believe to be the coolant flow on my Mercruiser 4.3l.

Option A

My thought is that if I use the hose fitting for freshwater and don't run the engine then I would only be flushing the elbow and nothing else. Yellow path in the sketch. Depending on the water flow I risk having water flow into the exhaust and in to the cylinders. If I keep the water flow to a trickle I should be good, correct?

Is it true that the elbows corrode at a faster rate than the Manifolds? Maybe because they aren't flooded with water when not running and air enables more corrosion to occur? Not sure, but I read somewhere that elbows fail quicker/more often.

Option B

If I run the engine with the Freshwater supply connected, and the T-Stat is open, I would be flushing with a mixture of saltwater from the outdrive impeller and the Freshwater from the Flush fitting. Let me know if that sounds correct. If you look at the sketch then I would be able to have flow on the Yellow, Green and Orange path. The issue is that the impeller and Freshwater would be mixing at that plastic "T" that I spoke about and then a slightly less salty solution will be left in the engine. Seems better but not the best flush.

Option C

I read a few boat owners had installed a barbed fitting in to the drain plugs on the manifolds, then ran a hose from both of them to a "T" and then to a freshwater hose connection quick connect or capped hose fitting. They would shut the engine off, Hook up the hose and slowly feed freshwater into the system which would mix and flush the manifold and elbows. I'm really only concerned about those two parts as they are the two that need regular replacement due to corrosion. With this setup I would need to be careful of the water flow so I don't fill up any cylinders. I've never seen the inside of the riser to know how much flow it would take to do that. Maybe when I replace the manifolds this spring it will make more sense to me when I see the inner cavities of the elbows (risers).

Let me know your thoughts and what you feel is the best way to extend the life of the elbows and manifolds. Sorry but I couldn't figure out how to insert an image. I would choose the Jpg and then it would never show in the post so i had to make a PDF attachment.

I'm new to boating and want to start next year flushing after every trip. My boat has a hose fitting on the swim deck that I tried to trace yesterday but being it's behind the motor I couldn't verify the exact routing. I could barely see that it leads into an off-white plastic housing and then splits to two hoses. One hose I could tell leads to the T-Stat housing and the other I'm assuming goes to the PS Cooler and then down to the Outdrive impeller, which would be the raw water supply during normal operation. The sketch I attached is what I believe to be the coolant flow on my Mercruiser 4.3l.

Option A

My thought is that if I use the hose fitting for freshwater and don't run the engine then I would only be flushing the elbow and nothing else. Yellow path in the sketch. Depending on the water flow I risk having water flow into the exhaust and in to the cylinders. If I keep the water flow to a trickle I should be good, correct?

Is it true that the elbows corrode at a faster rate than the Manifolds? Maybe because they aren't flooded with water when not running and air enables more corrosion to occur? Not sure, but I read somewhere that elbows fail quicker/more often.

Option B

If I run the engine with the Freshwater supply connected, and the T-Stat is open, I would be flushing with a mixture of saltwater from the outdrive impeller and the Freshwater from the Flush fitting. Let me know if that sounds correct. If you look at the sketch then I would be able to have flow on the Yellow, Green and Orange path. The issue is that the impeller and Freshwater would be mixing at that plastic "T" that I spoke about and then a slightly less salty solution will be left in the engine. Seems better but not the best flush.

Option C

I read a few boat owners had installed a barbed fitting in to the drain plugs on the manifolds, then ran a hose from both of them to a "T" and then to a freshwater hose connection quick connect or capped hose fitting. They would shut the engine off, Hook up the hose and slowly feed freshwater into the system which would mix and flush the manifold and elbows. I'm really only concerned about those two parts as they are the two that need regular replacement due to corrosion. With this setup I would need to be careful of the water flow so I don't fill up any cylinders. I've never seen the inside of the riser to know how much flow it would take to do that. Maybe when I replace the manifolds this spring it will make more sense to me when I see the inner cavities of the elbows (risers).

Let me know your thoughts and what you feel is the best way to extend the life of the elbows and manifolds. Sorry but I couldn't figure out how to insert an image. I would choose the Jpg and then it would never show in the post so i had to make a PDF attachment.