BruceWayne426

Member

First of all, thanks to racerone and others who assisted me a few months ago with my OMC 40 hp military motor starter. Racerone went above and beyond to identify what my motor really is and filling is some very interesting facts.

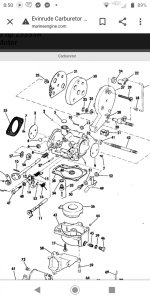

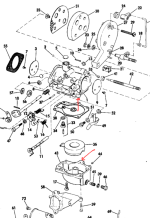

Now to the problem at hand. I am assisting a friend who purchased a 1973 Johnson 25 hp Model 25RL73A. He purchased it "as is" and it was not running when he brought it to me. I checked for spark and it had a good strong spark from both plugs. Compression was 92 in both cylinders. I think that is a little low but thought it should run. I then pulled the carb and found several issues. The screw plug at the bottom of the bowl was missing and the hole was filled with caulk! After disassembling, the gasket inside the bowl was missing as was the gasket around the idle jet. The needle valve was not connected to the float with the wire mechanism. I replaced the missing gaskets, screw plug, and a new needle valve and seat. I cleaned up the caulking and soaked the carb in cleaner for two nights. I can run a wire through the passage ways including the three small holes in the throat. I installed new gas lines and gas pump. The motor will start if I spray (mixed) gas down the carb throat but will not stay running. My next thought was the leave valves. I took the intake off and cleaned the crud off the intake plate. The leaf valves looked good. One casked looked almost new but the other was trash so I replaced it. I also replaced the head gasket. Still no changed. It will start with a little squirt of gas but will not stay running. If I pull the screw plug and pump the gas bulb, gas flows freely.

What am I missing?

Sorry this got so long but I am wanted you all to know what I have done so far. Any and all suggestions are greatly appreciated.

wf all, I would like

Now to the problem at hand. I am assisting a friend who purchased a 1973 Johnson 25 hp Model 25RL73A. He purchased it "as is" and it was not running when he brought it to me. I checked for spark and it had a good strong spark from both plugs. Compression was 92 in both cylinders. I think that is a little low but thought it should run. I then pulled the carb and found several issues. The screw plug at the bottom of the bowl was missing and the hole was filled with caulk! After disassembling, the gasket inside the bowl was missing as was the gasket around the idle jet. The needle valve was not connected to the float with the wire mechanism. I replaced the missing gaskets, screw plug, and a new needle valve and seat. I cleaned up the caulking and soaked the carb in cleaner for two nights. I can run a wire through the passage ways including the three small holes in the throat. I installed new gas lines and gas pump. The motor will start if I spray (mixed) gas down the carb throat but will not stay running. My next thought was the leave valves. I took the intake off and cleaned the crud off the intake plate. The leaf valves looked good. One casked looked almost new but the other was trash so I replaced it. I also replaced the head gasket. Still no changed. It will start with a little squirt of gas but will not stay running. If I pull the screw plug and pump the gas bulb, gas flows freely.

What am I missing?

Sorry this got so long but I am wanted you all to know what I have done so far. Any and all suggestions are greatly appreciated.

wf all, I would like