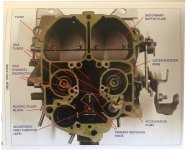

New to board and i've spent weeks working on this problem and researching the net for ideas and tips. I'm hoping to get some fresh ideas on what to do next.<br><br>New to me 87 4 winns with a 305 and merc outdrive. A month or so ago, on a hot day, it heat soaked and I decided to take a look at the carb and replace the fuel separator while i was there. Overall ran well before i took it off. Carb wasn't too dirty but given that i didn't know when it was last rebuilt i decided to do maintenance. Bought a rebuild kit, replaced the float, acc pump, all gaskets. Took everything apart except the choke, soaked in ultrasonic carb cleaner, out it all back together.<br><br>Idles fine, and shoots fuel from acc pump but idle mixture is not responsive. All of this on muffs.<br><br>Have the idle down low (500-600 rpm) so it shouldn't be pulling from main circuit. I sprayed around the carb to look for leaks but couldn't find any (and wouldn't this have caused idle to be high?)<br><br>I did notice that my choke isn't fully opened - would that cause any issues? I will fix that.<br><br>The kit didn't include the thick (1/4") base gasket. I originally installed the carb with the thin gasket and then read on net that people have had trouble tuning with it so i reinstalled the thick one. No difference. Also reinstalled the original mixture screw since the new one looked a little different - no difference.<br><br>I double checked the float level with the ruler and it's spot on. No visible drips of fuel into the bowl when idling.<br><br>What i don't know if whether it matters which needle assembly to use. Kit shows 2 methods: one with a spring and one without. when i took mine apart it didn't include the spring so i adjusted the float level without the spring based on the rebuild sheet. Would a bad float level cause my problem and wouldn't i see fuel dripping from venturi if so?<br><br>I haven't checked the timing but seems like i should be able to adjust the mixture even if the timing was a bit off. I'll check that too.<br><br>The only thing i can think of is that the idle mixture seat got damaged and there is fuel passing through the circuit even though the screw is in. Seems a bit far fetched to me - can it be that enlarged?<br><br>Out of ideas and very frustrated with this carb. Welcome any feedback and ideas.<br>Thanks in advance<br>Patrick<br><br><br>

Home

Outboard Motor Parts

Chrysler outboard parts Evinrude outboard parts Force outboard parts Honda outboard parts Johnson outboard parts Mariner outboard parts Mercury outboard parts Suzuki outboard parts Tohatsu outboard parts Yamaha outboard partsInboard & Sterndrive Engine Parts

Chrysler Marine inboard parts Crusader Marine parts MerCruiser sterndrive parts OMC sterndrive parts Pleasurecraft Marine parts Volvo Penta marine parts + MoreAll Engine Brands

All Manuals HomeOutboard Repair Manuals

Chrysler outboard manuals Evinrude outboard manuals Force outboard manuals Honda outboard manuals Johnson outboard manuals Mariner outboard manualsMercury outboard manuals Nissan outboard manuals Suzuki outboard manuals Tohatsu outboard manuals Yamaha outboard manuals

Inboard & Sterndrive Engine Manuals

MerCruiser sterndrive manuals OMC sterndrive manuals Volvo Penta marine engine manualsPlease Note

MarineEngine.com does not offer troubleshooting assistance or repair advice by email or by telephone.

You are invited to join our public Boat Repair Forum to seek assistance from other members.

You may also visit the Boat Motor Manuals section of our site to obtain a service manual.