hungyzerglin

New member

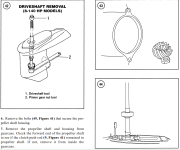

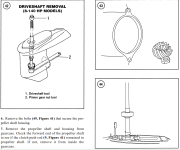

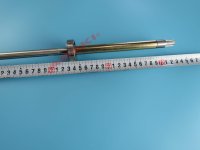

I'm taking apart a 8HP NS8B two stroke lower unit since I found milky gear oil. I managed to pull the bearing carrier and prop shaft out but I'm stumped on how to pull out the driveshaft. The service manual says to use a special splined tool on the driveshaft to spin off a pinion gear retaining nut, but I don't see a retaining nut, seems to me like the driveshaft is just held in place with an interference fit on the caged ball bearing mated to the gearcase body in pic 2. If so, how does one press out/pull out the bearing to replace it?