Joey White

Member

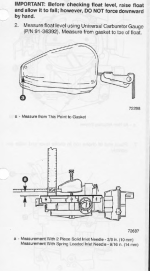

Since I have been trying to get my boat (1989 EBKO Monte Carlo) engine (Mercruiser 4.3l v6) to run I can't seem to not find problems, most of them I feel like are just because I don't know much about these GM marine motors. There is carburetor issues that I will hopefully be able to figure out, and one thing that I feel might be attributing to that is my fuel pump. So when I got this boat it came with an electric in-line fuel pump which I would imagine was not stock, since then I bought a 4-7 psi inline fuel pump for some testing with the engine, but the carburetor keeps flooding after usually 15-30 secs of just the pump running, not sure if this makes a difference but when it floods it comes out the venturis. So thinking that maybe I have to much fuel pressure I got a fuel pressure regulator which I make the pressure set to 5 at most, same problem. I was thinking that maybe I should just go with the stock fuel pump, but I couldn't see where it connects to the block. The first image is a spot on the intake manifold that I'm not sure what purpose it serves, at first I thought maybe the fuel pump goes there, but it doesn't look like it either. The second image, from what I could find, on the right side of the block is where the fuel pump is suppose to be mounted to the block, but there appears to be not bolt holes to mount it to. I've even lately been having electrical issues with this engine. So any help would greatly be appreciated to help get my project going in the right direction.

https://i.imgur.com/MhxdY3G.png

https://i.imgur.com/1w2ehOh.jpg

https://i.imgur.com/MhxdY3G.png

https://i.imgur.com/1w2ehOh.jpg