ebacon

Contributing Member

Hello all,

I bought a 1975 Johnson 9.9 HP that needs a little work. It will go on a 12' aluminum V-hull. The engine runs and appears to have a new carb. I started this thread to document the project and look forward to getting to know you all in this sub-forum. I will attach a few photos of the engine later. I forgot how to use the forum software.

The engine needs:

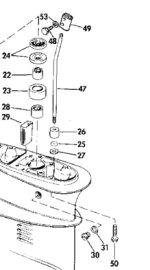

1) a new prop shaft seal

2) a new fuel line between the filter and carb

3) realignment between the indicator mark and associated positions (START/SHIFT, etc) on the twist tiller

4) Once the engine is running fine I would like to fix its cosmetics. It's a bit rough looking.

I read through the forums and it appears that some 9.9 and 15 HP engines are the same except for the carbs. Can my engine be upgraded to 15 HP? All of the examples that I saw of 9.9 HP being upgraded to 15HP appear to be dual carb engines. My engine has a single carb.

I bought a 1975 Johnson 9.9 HP that needs a little work. It will go on a 12' aluminum V-hull. The engine runs and appears to have a new carb. I started this thread to document the project and look forward to getting to know you all in this sub-forum. I will attach a few photos of the engine later. I forgot how to use the forum software.

The engine needs:

1) a new prop shaft seal

2) a new fuel line between the filter and carb

3) realignment between the indicator mark and associated positions (START/SHIFT, etc) on the twist tiller

4) Once the engine is running fine I would like to fix its cosmetics. It's a bit rough looking.

I read through the forums and it appears that some 9.9 and 15 HP engines are the same except for the carbs. Can my engine be upgraded to 15 HP? All of the examples that I saw of 9.9 HP being upgraded to 15HP appear to be dual carb engines. My engine has a single carb.