bigjohnson

Regular Contributor

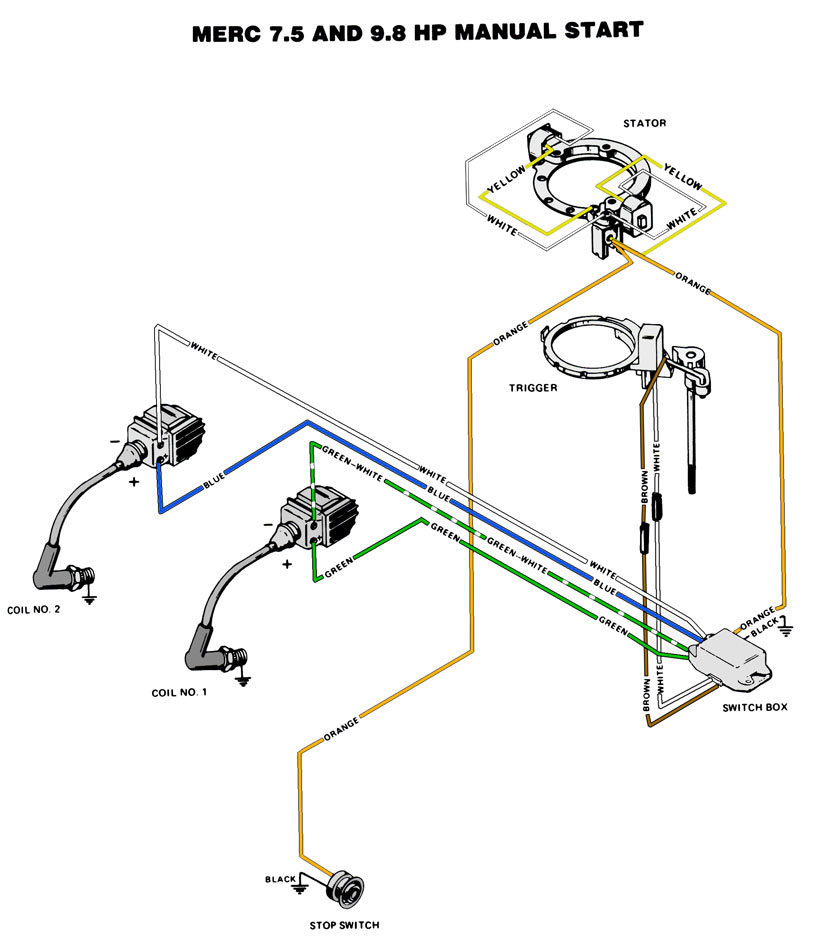

Recently found a 1980 mercury 7.5hp comet lightning. It needs a lot of TLC but it looks like a good motor worth fixing up.

Anyone know where I can find a mercury service manual for this.

Prefer MERCURY.

Anyone know where I can find a mercury service manual for this.

Prefer MERCURY.