I’ve just picked up this motor for the kids (and me), to put on a 10” tinny. I checked the compression and it’s down to 60psi both cylinders (cold). Does this indicate a re-build is necessary (or rings at least)? It’s been sitting for about 3 years and isn’t actually running at present (prior to that it was running fine, so I suspect fuel pump or carbi as it fires up straight away with a squirt of fuel into the cylinders, but only for a second or so. I know I shouldn’t do that with a 2 stroke, but just needed to prove a point). Seems there’s very few parts available for these - I guess people just throw these little ones away, but I really don’t want to do that if I can avoid it. Any thoughts be greatly appreciated.

Home

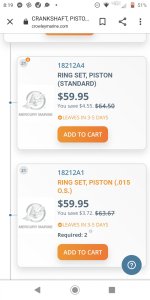

Outboard Motor Parts

Chrysler outboard parts Evinrude outboard parts Force outboard parts Honda outboard parts Johnson outboard parts Mariner outboard parts Mercury outboard parts Suzuki outboard parts Tohatsu outboard parts Yamaha outboard partsInboard & Sterndrive Engine Parts

Chrysler Marine inboard parts Crusader Marine parts MerCruiser sterndrive parts OMC sterndrive parts Pleasurecraft Marine parts Volvo Penta marine parts + MoreAll Engine Brands

All Manuals HomeOutboard Repair Manuals

Chrysler outboard manuals Evinrude outboard manuals Force outboard manuals Honda outboard manuals Johnson outboard manuals Mariner outboard manualsMercury outboard manuals Nissan outboard manuals Suzuki outboard manuals Tohatsu outboard manuals Yamaha outboard manuals

Inboard & Sterndrive Engine Manuals

MerCruiser sterndrive manuals OMC sterndrive manuals Volvo Penta marine engine manualsPlease Note

MarineEngine.com does not offer troubleshooting assistance or repair advice by email or by telephone.

You are invited to join our public Boat Repair Forum to seek assistance from other members.

You may also visit the Boat Motor Manuals section of our site to obtain a service manual.