.......... I is a special forged merc. crank. Hans, the machinist said there is added weight to the crank and then he looked at my old rusty flywheel and said it has no weights, its neutral.

That's good news then.

The crankshaft is a

rre mercruiser internally balanced forge crank.

what is rre ....... typo..... rare????

There was also a much heavier fillet radii on both mains & rod journals than I see on other sbc cranks. Upon a little more digging about bearings< I believe I need "H" series bearings which are chamfered more and slightly narrower??? Clevite ok? we use them in diesels.

I would suggest asking your machine shop person for a recommendation.

This is from SpeedWayMotors dot com:

Info

Clevite's H-Series was developed primarily for use in NASCAR type racing, but they are suitable for all types of competition engines. These sets are specifically for 1969-Up 302-305-327-350 S/B Chevy.

- Use H-series bearings with crankshafts that have oversize fillets and where engines run in the medium to high RPM range.

- H-Series bearings should be used if contact patterns obtained with P-series parts are too narrow. Contact pattern should ideally cover 2/3 to 3/4 of the bearing surface.

- If you aren't sure which type of performance bearing to start with, the H-Series will be your best choice.

I want decent forged rods & pistons ("I" beam rod, LCQ piston) Can you guys recommend rods that upper part of journal that is tapered to help with cam clearance and I realize I'll have to do some clearance work around the bottoms of cyl. bores and also casting around block near oil pan. I am having the machinist bore the hole in fuel pump mounting boss for a mechanical pump, Is that okay?

If they have the proper jig or fixture for boring the push rod hole, yes.

Make sure that your camshaft offers the fuel pump lobe.... I believe that most will.

Or do you guys all run electric pumps?

The electric fuel pumps work well.

However, with the electric fuel pump, you will also need to install the wiring and the LOPS (low oil pressure switch).

The LOPS must be able to cut the power to the fuel pump in the absence of engine oil pressure.

USCG rule.

Along with this system, you will want to create a "start-by-pass" circuit that will energize the fuel pump prior to engine oil pressure coming up.

If you go with the electric, I can help you with a wiring diagram.

Thanks on the pump pic. Rick, that maybe the same pump i have, I haven't seen it in year, Its been in storage. Came off bbc, Im not sure I might have to do some machine work on mounting flange if bolt pattern is different from bbc to sbc damper.

Actually, the Crankshaft Pump's mounting flange attaches to the crankshaft pulley, and uses the three bolt holes in the harmonic balancer spokes.

The pulley will have two (2) stamped/raised dowels that will correspond to the pump's flange for alignment.

The flange will actually bolt on in one of three indexings.... but only one indexing will be correct.

(it will make sense to once you start installing it)

I agree Rick on the weight and other benefits of Alum. intake. I just couldnt bring myself to go with Alum. heads, even with full closed cooling...

FYI... aluminum cylinder heads (along with a nice tight quench dimension) will allow you to increase your S C/R some.

This is due to the more efficient cylinder head "heat dissipation". Not necessary.... I'm just tossing that out there.

Torque loads, Salt water, ya know, I guess Im old school.

With your Closed Cooling System, the heads and intake manifold will never see salt water.

........ Im also confused about timing chain sets, I know double roller will obviously be deeper, requiring deeper T-chin cover.

Let the cylinder block determine which timing chain cover it requires.

If going with a roller cam and roller cam followers, the cover must work with that set up.

Again, these would be good questions for your machine shop person.

Will that leave me sufficient room between water pump?

All of your belt driven accessories, and their alignment, will be based on the short body coolant circulating pump (i.e., water pump).

Make sure that the pump clears the timing chain cover.

SBC Coolant Circulating pump.... ( called a water pump in a misnomer fashion )

and how about snout depth on the damper for pulley alignment?

I was going to ask earlier if you knew if the 400 harmonic balancer must be used with the Merc 377 crankshaft.

I mentioned that earlier........ that's a good question for your machine shop person.

I was going to use all the original bolt on hardware, like p.s. pump, alt. etc. all "V" belt drive from boats original 5.7 non Vortec. I do still have the serpentine set up from original MPI stroker but everything is rusted pretty bad from sinking. I also have to consider the room for the closed cooling system possibly between the the two styles of pulley systems, although you can probably get for both. I guess Ill take my time until I hear how the block turned out. Ill just order the .010 mains and do my oil passage porting work and block clearancing. Im jumping ahead of the gun as usual,

I obviously cant order rods and pistons because I dont know what deck hieght will be yet,

You will need these parts before determining that!

..... Are you going with the 5.7" rods? Keep in mind that the longer rods move the wrist pin further into the piston, creating shorter skirts.

Hot Rod guys like the shorter skirts... but I think that the longer skirts work best in the Marine version. There are other dynamics that come into play also.

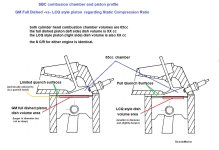

..... Are you going with the LCQ style pistons? A good choice with the Vortec cylinder head quench surface.

..... Do you know what Vortec cylinder head combustion chamber volume is? They differ slightly.

I may even deck off a little material on the new heads, then check comb. chamber c.c..

Don't touch the heads just yet!

Do the math on the cylinder block first ... i.e., deck height, desired quench dimension, compressed head gasket thickness, etc.

I dont want to have the pistons sit too far down in the jugs.

Exactly!

If the piston deck dimension is excessive, in order to obtain a good quench dimension the compressed head gasket thickness would need to be very thin!

Piston deck dimension + compressed head gasket thickness = quench dimension.

Your shop will know exactly what to do.

Please see my images in the thread that I linked you to earlier.

NOTE: the HP Auto guys shoot for a larger quench dimension. For your Marine build, you will want to be a bit tighter!

Can you guys recommend a good place to do my parts purchasing that might have people that would work with me through that process?

I'd suggest reading articles by people like Jeff Smith and the others mentioned in post #26.

Some of these guys represent companies who manufacture and sell these parts.

Keith Black, for example.

Dennis Moore has a wealth of knowledge to share, and he is an authority on the SBC Marine engine.

Granted, most of these men represent HP Auto. However, a great deal of the info can be applied to the Marine SBC engine.

One last thing.... Ignition System!

You will eventually need to decide upon an ignition system.

With your Q/E build, your system can now throw a tad bit more TA at the engine.

More on that later!

Keep up the good work and your good research.

You'll get there!