Hello all, im new to volvo outdrives and inboard motors as well for that matter. I stumbled across this site while researching parts etc on a boat i was recently given and have to say I'm impressed with the community's knowledge!

I'll post some pictures shortly but id appreciate any help with ID of my motor and outdrive as well as suggestions.

I was given a 1978 Sea Ray SRV240 from a family member, the boat is in really quite good condition and was running when parked in 2015. The rear portion of the cover was damaged at some point and some cats got in as well, so there was some cleaning and wood refinishing that needed done and I've gotten alot done in that department. I was hoping to change oil and rubber hose impeller etc and fire this beast up but when pumping out the crankcase i found about 2 qts of water in there. I pulled the heads and everything but one cylinder looked good, some rust one near the top but i may be able to hone it and be ok. with that much water in there though im pulling the motor to make sure the crank wasn't sitting in water and (hopefully) just clean everything hone, rering and new gaskets. Anyways, if you'd be so kind to divulge some of your knowledge i do have some questions!

valve covers say "volvo penta 255a" i havent much about this at all, block numbers say its a 68-70 Chevy 350, its has .60 over pistons (i did find on rebuild receipt for engine cicra 1999) and it has a holley marine 4bbl card and an adapter plate- carb #'s indicate it was for a 351W ford. The boat was all raw water cooling, i have a marine heat exchanger so i think during this process I'm going to hook that up and make it a 1/2 closed system. Seems like a fairly simple project and the benefits seem worth it to me.

the sterndrive as a "280" id plate on the removable cover, the billows need replacing and some wasps had made a home in the outdrive intake and exhaust inlets. the inside of the outdrive only has a yellow sticker and no ID plate that i can find. the outdrive oil was clean and clear and i could tell the system was sealed.

-does this sterndrive take 90w marine gear oil? or 30w engine oil? recommendations or type brand?

-with engine out should i pull the rest and go thru it? new bearings, change shield seal? (shield has sealant all around outboard edge although no indication its leaking) there was some oily gunky stuff in the drive bellow about 2 ounces. I also broke one bolt taking the outdrive off but i can retap that i think, the bolt that holds the side gudgeon pins in.

-for putting stern drive back on i see its easier to remove the transmission and do it in 2 parts, anything special about that procedure besides remove and replace (with gear oil drained)? some kind of shimming procedure or something?

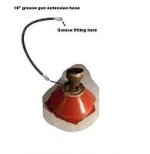

-what transom shield is it i have? i see some very cheap online and some very expensive.

-part number for hose on transom shield the exits down at the 5oclock position? or suitable replacement hose for this.

Im excited to get this boat back on the water (freshwater murky texas lake) that you all in advance for any help and advice, pictures coming shortly.

I'll post some pictures shortly but id appreciate any help with ID of my motor and outdrive as well as suggestions.

I was given a 1978 Sea Ray SRV240 from a family member, the boat is in really quite good condition and was running when parked in 2015. The rear portion of the cover was damaged at some point and some cats got in as well, so there was some cleaning and wood refinishing that needed done and I've gotten alot done in that department. I was hoping to change oil and rubber hose impeller etc and fire this beast up but when pumping out the crankcase i found about 2 qts of water in there. I pulled the heads and everything but one cylinder looked good, some rust one near the top but i may be able to hone it and be ok. with that much water in there though im pulling the motor to make sure the crank wasn't sitting in water and (hopefully) just clean everything hone, rering and new gaskets. Anyways, if you'd be so kind to divulge some of your knowledge i do have some questions!

valve covers say "volvo penta 255a" i havent much about this at all, block numbers say its a 68-70 Chevy 350, its has .60 over pistons (i did find on rebuild receipt for engine cicra 1999) and it has a holley marine 4bbl card and an adapter plate- carb #'s indicate it was for a 351W ford. The boat was all raw water cooling, i have a marine heat exchanger so i think during this process I'm going to hook that up and make it a 1/2 closed system. Seems like a fairly simple project and the benefits seem worth it to me.

the sterndrive as a "280" id plate on the removable cover, the billows need replacing and some wasps had made a home in the outdrive intake and exhaust inlets. the inside of the outdrive only has a yellow sticker and no ID plate that i can find. the outdrive oil was clean and clear and i could tell the system was sealed.

-does this sterndrive take 90w marine gear oil? or 30w engine oil? recommendations or type brand?

-with engine out should i pull the rest and go thru it? new bearings, change shield seal? (shield has sealant all around outboard edge although no indication its leaking) there was some oily gunky stuff in the drive bellow about 2 ounces. I also broke one bolt taking the outdrive off but i can retap that i think, the bolt that holds the side gudgeon pins in.

-for putting stern drive back on i see its easier to remove the transmission and do it in 2 parts, anything special about that procedure besides remove and replace (with gear oil drained)? some kind of shimming procedure or something?

-what transom shield is it i have? i see some very cheap online and some very expensive.

-part number for hose on transom shield the exits down at the 5oclock position? or suitable replacement hose for this.

Im excited to get this boat back on the water (freshwater murky texas lake) that you all in advance for any help and advice, pictures coming shortly.

Last edited: